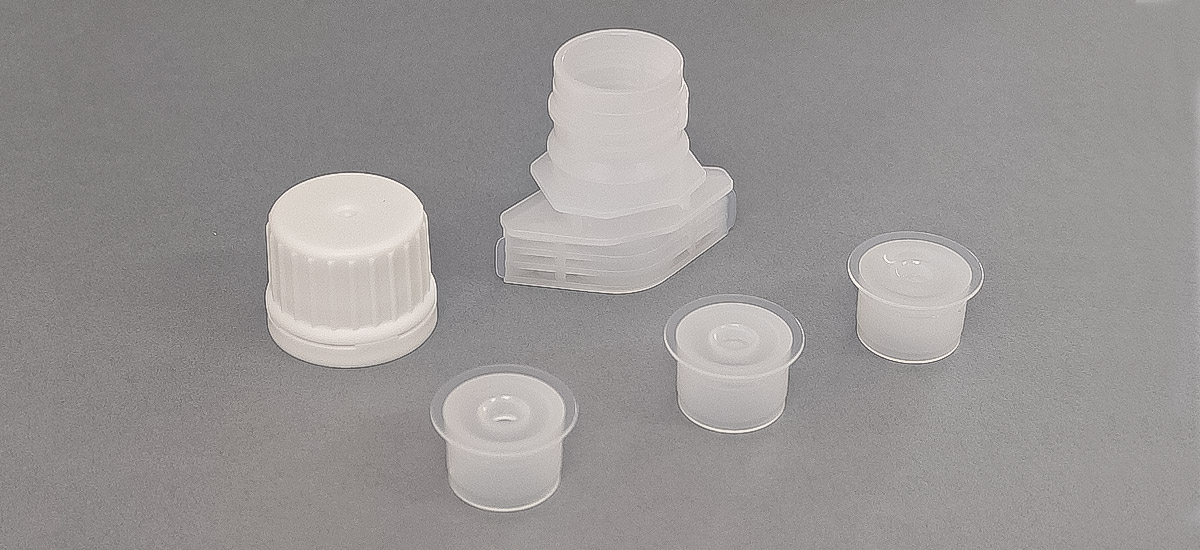

Aska Company is developing spouts and spout caps with distinctive original shapes.

In our previous Market News, we introduce the development of narrow spouts and hinge caps that we can put in a post.

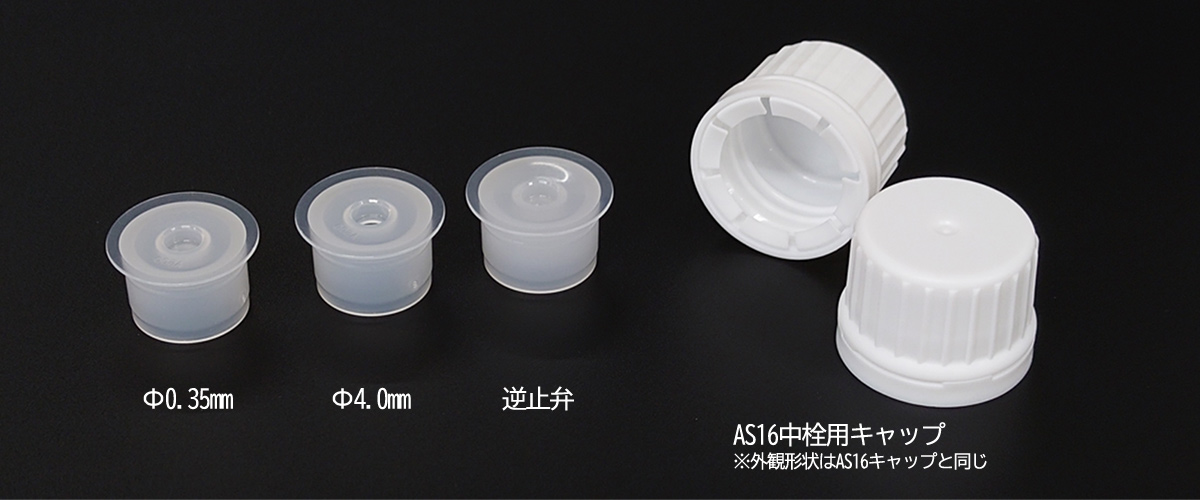

In this issue, we will report on the "AS16 Spout Inner Plug Specification" as a continuation of the report.

What is the "AS16 Spout Plug Specification"?

Aska Company is developing a middle plug version of the AS16 spout.

Here is how we use it.

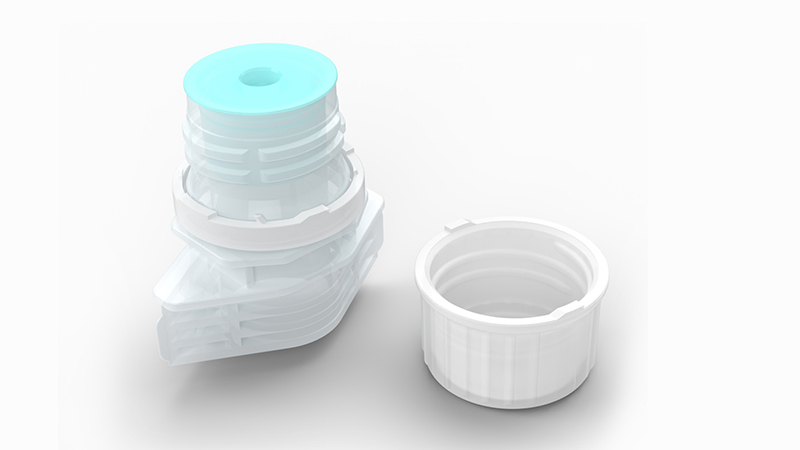

①Set the cap

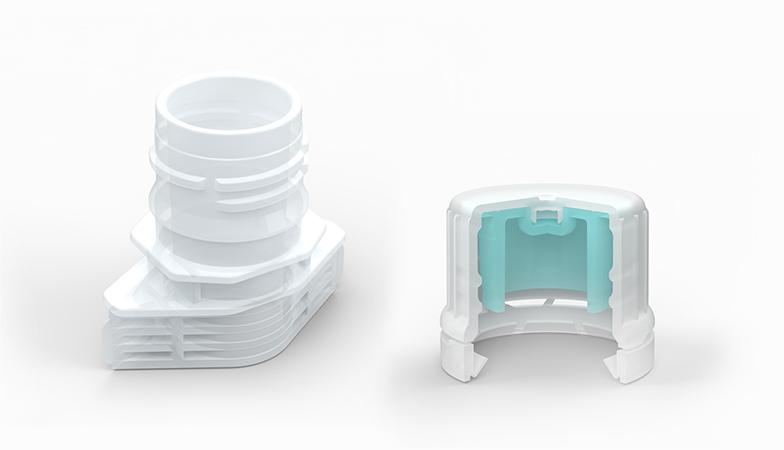

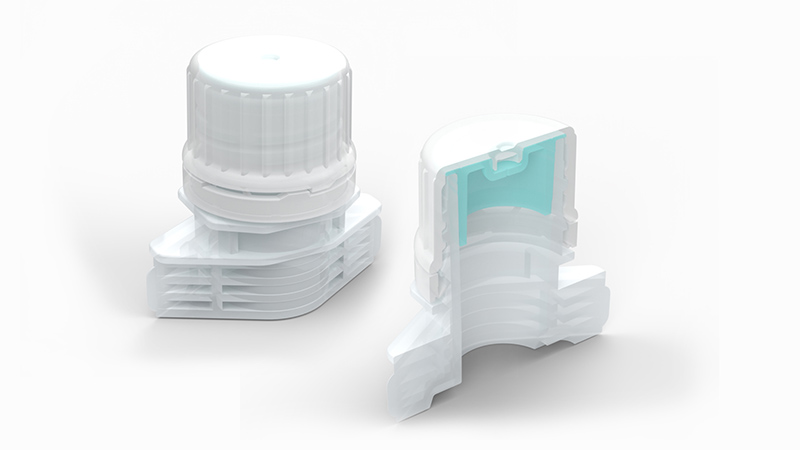

The cap has a pre-installed inner plug. Thus you can close the cap like a normal screw cap.

②Tighten the cap

By tightening the cap, the inner plug set in the cap is fitted into the spout side to form a spout with an inner plug.

You can open the cap in this state without removing the inner plug from the spout.

You can fill the contents from the φ16 diameter, and you need to cap the inner plug.

You don't need to modify the conventional production line.

Since the dimensions of the external part are the same as those of a regular spout and cap, there is no need to modify the line in terms of cap outer diameter, etc.

Since our hinge caps do not have a tamper-evident mechanism, some customers have hesitated to adopt our hinge caps because of the difficulty in ensuring virginity.

We can offer shrink processing of the hinge cap, but there is a concern that this would increase the number of processes.

With the newly developed inner plug, it is possible to have both a tamper-evident mechanism (flap part) such as a screw cap and a choice of diameter sizes, a hinge cap, without changing the production line or adding another process.

If you need tamper-evident for low-viscosity contents, this inner plug specification can fill your requests.

Various verifications continue.

We are still continuing various verifications on the spout of this inner plug specification.

First, we are continuing research on the fit between the spout and the inner plug to find the optimal solution for the strength of the fit between the spout and the inner plug so that the inner cap does not come off due to the internal pressure when we discharge the contents.

Next, we also continue to verify the presetting of the cap and the inner cap to ensure that the inner cap does not fall off during transportation.

It will be a little while before we can deliver the product to you as a product, but we can provide you with a sample product, so please feel free to contact us if you are interested.

This time, we have introduced a new spout lineup with an inner cap.

In addition to the spouts introduced in this article, we have many other products under development.

Please look forward to hearing more about the development of the new AS Spout series in the future.

As an injection molding manufacturer, Aska Company will continue to develop unique and user-friendly products.

Writer:いなむら