Life science, food, cosmetics, stationery, toiletries, etc.

We are developing our business in various fields

by utilizing our knowledge and know-how cultivated through plastic manufacturing.

New Topics(BLOG)

Visit to China - Interviews for Specific Skilled Employees and Market Trend Research Trip - [ASKA MARKET NEWS Apr. 2025, No. 362]

Aska Company's Idea of “Specific Skill System” In January 2025, we went to China for recruitment interviews for specific skilled employees and market research. As the Aska Company itself plays the role of a receiving organization for the recruitment interviews of specific skilled employees, we are in direct contact with our counterpart companies in China and provide comprehensive support for specific skilled employees from their arrival in Japan to their return home. And as of February 2025, Aska Company has hired 14 Chinese specific skilled employees. The Aska Company's specific skill system is designed to achieve a higher standard for our specific skilled employees. In addition to simply adhering to labor standards, we also focus on supporting their Japanese language studies and actively support their acquisition of Japanese language proficiency test (N1 to N5) qualifications. For example, we are working to create an environment that facilitates learning for employees with specific skills by providing educational opportunities during overtime hours. Market Research in China We visited markets and supermarkets to learn about Chinese life and culture. Unlike in Japan, measuring and selling is the norm, and consumers generally decide the quantity and weight of products and purchase them by themselves. Consumers are able to get only the amount they need, which helps reduce food loss and promotes economically and environmentally sustainable consumption. In addition, cashless payments utilizing smartphones are rapidly spreading, especially in urban areas, where most people use QR codes to make payments. Furthermore, a payment system based on facial recognition was also introduced. This ...

Introduction of “Spout Pouch with Mist Pump” Development [ASKA MARKET NEWS Mar. 2025, No. 361]

The Aska Company has been developing original products named “AS Family”. In 2019, we developed the first spout and cap for spout pouch container applications and started manufacturing and selling them. Since then, many customers have adopted our products. In terms of marketing, we have built a system to speed up development and are accelerating the proposal of new forms of spout pouches. In this issue, we would like to introduce the “Spout Pouch with Mist Pump” currently under development. As an extension of the variation of spout pouch containers Spout pouch containers are increasingly being used in a wide range of business fields for their convenience and reduced environmental impact. In Japan, they are not only used for refill purposes, but are also increasingly adopted as unique containers. They are used not only in the general consumer market, such as drugstores, but also in specialized fields, such as medical and industrial applications. Overseas, they are also being developed in accordance with the culture and market characteristics of each country. The AS family product lineup continues to expand, with 7 types of spouts and 19 types of caps currently available. In addition, we are actively developing new products. These new products were introduced at the Tokyo Pack in October 2024. https://www.youtube.com/watch?v=kBdmiVUKfFk Characteristics of the developed product “Spout Pouch with Mist Pump" We are constantly developing new spout pouch supplies. Previously, we developed and commercialized the AS18 spout and AS26.5 spout series that can be connected to pumps. Now we are developing “spout pouches ...

Introduction of seminars offered by Aska Company [ASKA MARKET NEWS Feb. 2025, No. 360]

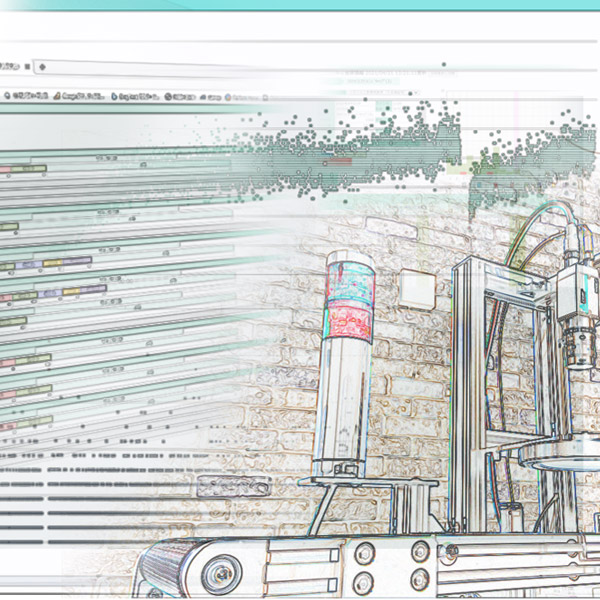

Aska Company has been offering a variety of seminars since 2016. In this issue, we would like to introduce each seminar, whose contents are continuously being upgraded on a daily basis. Current Seminar and Future Plans We are currently offering seminars, but we are also planning to offer one workshop as a new form of know-how. Our seminars have been attended by a total of 114 companies and 690 guests since our first seminar in 2016, and have received a 98% understanding rate. (*From valid responses to the seminar questionnaire held in 2024) In addition, since the seminar is a private seminar for only 4 persons per company, you can freely ask any difficult questions you may have! We have experience in holding seminars for approximately 20 people, so please let us know for more details. (*We do limit the number of people who can tour the factory due to the limitations of the biological clean room.) In this issue of Market News, we are pleased to introduce three popular seminars and a workshop currently in the planning stages! Three Types of Popular Seminars ① Appearance Inspection Camera Seminar This seminar provides an opportunity to understand how visual inspection cameras work by actually seeing and touching them. This seminar is intended for those who know nothing about visual inspection cameras or have never seen one in person. You can learn how to set up an inspection decision using a visual inspection camera in three easy-to-understand steps. Even first-time users can start camera inspection operations with ...

ASKA's Products and Services “AS Family” [ASKA MARKET NEWS Jan. 2025, No. 359]

Thank you for reading Market News. In this issue, we would like to introduce you to ASKA Company's original products and services, “AS Family”. As a plastic molding manufacturer, we develop and produce a wide variety of plastic products. We have been providing products with specifications based on customer needs. Since 2020, we have been offering our original products “AS Spout Series.” They are related to spout pouch containers, and they are also environmentally friendly containers. We have also developed services such as seminars and equipment based on the ideas we have cultivated through manufacturing, and maintenance services using oxidation-reduction cleaning oven furnaces for dies and molds, which are important for product manufacturing. We have named these products and services “AS Family” and created a logo with the hope of further penetration. Aska's original products and services are collectively referred to as the “AS Family,” and in terms of products, the AS Series is represented as a group of plastic products. Thoughts on the AS Family Logo Regarding the logo shape, the overall form is inspired by the AS series product shape. We want to contribute to a recycling-oriented society! With this in mind, we used arrows to represent the social cycle, and expressed our wish that the growth rate of the recycling-oriented society will steadily increase. Map of Business Areas where ASKA COMPANY Contributes Here is the “Overall picture of the business fields to which ASKA COMPANY contributes” as expressed in our company brochure, which was updated in October 2024. In the previous ...

Introduction of Mold Storage and Management Methods [ASKA MARKET NEWS December 2024, No. 358]

Thank you for reading Market News. Aska Company manufactures about 50 molds per year, and this time we would like to introduce how we store our molds. Storage and Management of Molds The most important issue when storing molds is to prevent rusting. To prevent physical rusting, we use stainless steel for most of the product parts. As a general rule, we store molds indoors in a dedicated humidity-controlled warehouse. For management, we issue a mold code at the time the mold is manufactured or received, and manage the number in our in-house system. Storage and Management of Mold Parts In the case of prototype molds, the mold base is sometimes shared and only the product part is manufactured, so that many product parts exist in a single mold base. We manage the parts by tying them to the respective molds. In addition, some parts themselves do not have engravings, making it difficult to identify which part is which. If a sticker is applied to identify the part, it may peel off, and clearance is important for mold parts. Therefore, we have introduced laser markers in our MK activities (QC circle activities) and are using them to manage mold parts. Since molds and mold parts are expensive entrusted items, we will store and manage them with the utmost care. To Take Good Care of Molds We offer mold cleaning services. Please contact us if you are interested.

Intellectual Property Management at Aska Company [ASKA MARKET NEWS No. 357, Nov. 2024]

Have you ever heard of the term “Intellectual Property Rights?” At Aska Company, we are aware of our involvement in intellectual property, with several of our employees having obtained the National Intellectual Property Management Skills Test. We are also actively applying for and acquiring patents and design rights, which are included in intellectual property rights. In this issue, we would like to introduce “Intellectual Property Management”. What are Intellectual Property Rights? A system to protect what is created through intellectual creative activity as the property of the person who created it. The right to monopolize it for a certain period of time Among intellectual property rights, patent rights, utility model rights, design rights, and trademark rights are called industrial property rights, and are under the jurisdiction of the Japan Patent Office. Patent Right ... protects “inventions” Utility Model Rights … protect “devices” such as the shape, structure, and combination of articles Design Rights … protect “designs” such as the shape, pattern, and color of articles Trademark Rights … protect “marks” used to distinguish goods and services Advantages and disadvantages of acquiring intellectual property rights Once you acquire intellectual property rights, you can legally claim infringement of your rights in the event that a third party makes a counterfeit product. It is also effective in appealing your technological capabilities and building a relationship of trust. However, it must be kept in mind that after a certain period of time, the content of the invention will be made public. After the period of protection, anyone can freely ...

Introduction of PM Group's “Market Product Survey” [ASKA MARKET NEWS Oct. 2024, No. 356].

Thank you for reading Market News. In the February 2024 issue, we introduced the PM Group's workplaces and mentioned “Market Product Surveys”. In this issue, we would like to introduce you to Market Product Surveys in detail. What is the PM Group? The PM Group is an abbreviation for Product Management Group. It is the department in charge of prototype evaluation and standardization during product development, and is also responsible for overall project management. AS Family and AS Series The AS Family refers to original products, including cleaning and seminars, which are designed, developed, and marketed by the Aska Company based on know-how cultivated through years of experience. Among these products, plastic products are treated as the AS Series, and the lineup currently includes mainly spout caps for pouches. To develop the AS Series, it is first important to understand the market needs. To this end, we conduct market product surveys. Market Product Servey Here are some specific examples of the kind of research we conduct. ①Preparations We discuss within the department what products we will be researching. We often conduct research in genres related to products recently seen in the market or products under development. Once we have decided on the subject of the survey, we purchase the products on our own. We try to research at least 10 different products. ② Evaluations Once samples have been collected, evaluations will be conducted. The evaluation items include the following ・Appearance Observe and photograph cap and spout shapes (knurling and tamper-evident mechanisms) to determine ...

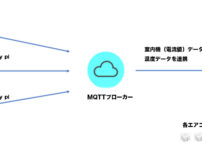

Promoting IoT to realize automatic control of air conditioners! [ASKA MARKET NEWS Sep. 2024, No. 355]

In this issue of Market News, we would like to introduce the automatic control of air conditioners in the production area of our headquarters S/N Factory as an example of the use of IoT. In our production area, several air conditioners are set to cooling all year round due to heat dissipation from the molding machines. However, the settings are constant regardless of high or low outside temperatures, and the number of air conditioners had not been reviewed. This time, we have taken steps to automatically control the air conditioners so that only the necessary amount of electricity is used while maintaining the room temperature in the production area. Grasp the operating status of HVAC equipment First, to determine the operation status of the outdoor units, we installed a current value measurement kit in the switchboard and obtained current values for one year. As a result, we found that the current values were low in winter when the outside temperature was low, and that only two of the six units were in operation. In addition, there were also events that repeated ON/OFF in a short period of time depending on the time of day. We found that the indoor unit automatically switches from the cooling setting to the air blowing setting in winter when the outside temperature is low, and that it operates unnecessarily. Air conditioner operation that does not rely on human intervention To eliminate unnecessary operation, temperature and current data were used to automatically turn the air conditioner on and off ...

Aska Company Contributions to Business Fields

Seminar

Camera Inspection Seminar: See, experience, and understand camera inspection

IoT/AI Application Seminar: Experience and learn IoT/AI

Nighttime Unmanned Factory Seminar: Developing "Thinkers" through Unmanned Factory

DX Seminar: What SMEs need to do to start DX

Molding Skill Seminar: Obtaining Injection Molding Know-How