Experience of IoT utilization in a factory where digital and human coexist

You can see effective coordination and collaboration of "big data" and "onsite capabilities" of the production line.

Participants will tour a factory that is in operation to see how we improve productivity.

You can learn how to utilize data through experience.

See, feel, and understand examples of IoT and AI utilization developed by SMEs

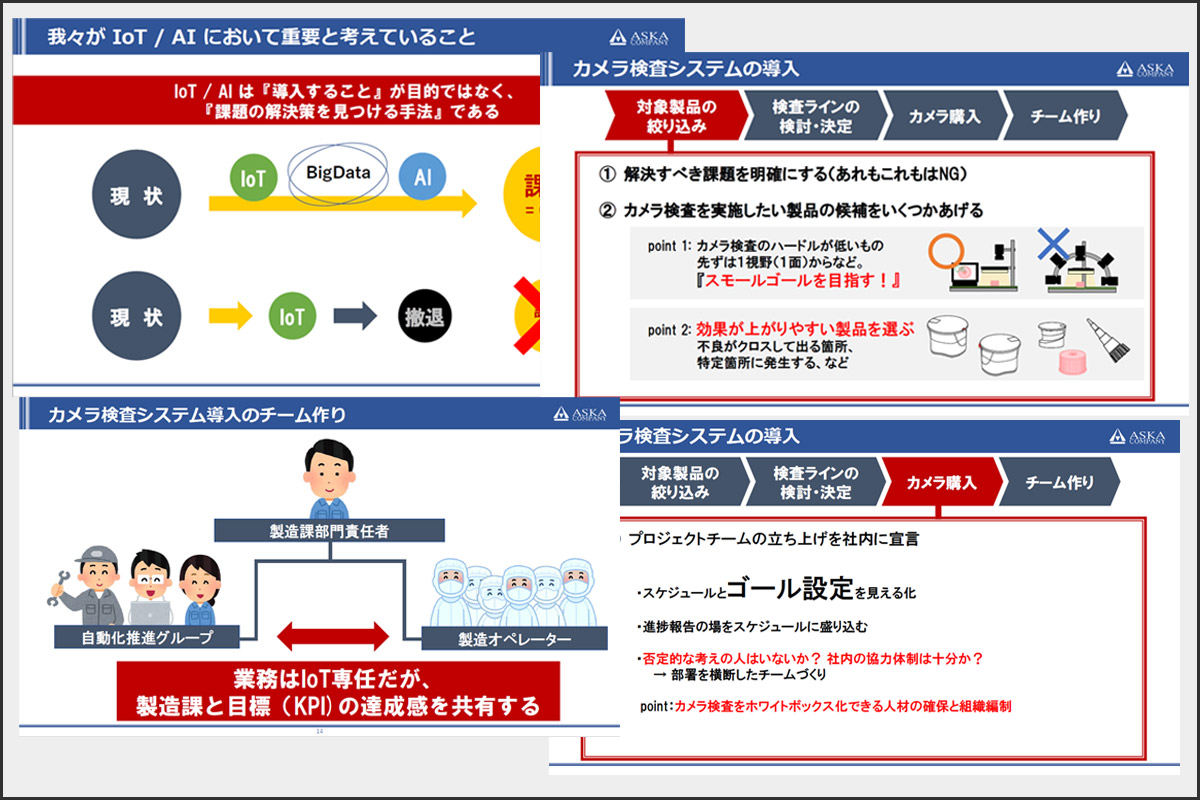

Observe examples of visualization and utilization of big data from camera inspection equipment and molding machine log data.

Experience how the same data can be seen and utilized in various ways anywhere in the factory and in the lectures.

This seminar is packed with know-how on IoT and AI utilization in production factories and is designed for actual utilization.

Seminar Outline

1. Private seminar for one company only

Unlike regular seminars, we hold this seminar only for one company.

Since there is no one from another company, we can customize the content as much as possible.

Also, you can freely ask questions as much as time permits.

2. Tour a factory in operation.

We will explain Aska Company's IoT and AI applications at a manufacturing site.

As a hands-on tour, you will also participate in a meeting at a manufacturing site where we utilize IoT to experience operational situations.

You will be able to experience how we share information via the network and how we utilize it.

Since we use high-function headsets, you can share the question-and-answer session in the factory with everyone.

3. You can see the 'real' such as records and documents.

In the seminar, we use actual documents and screens from past projects for explanations.

We explain the current status of the system, examples of failure prediction by AI system using mold clamping force, quality defect judgment, camera inspection data, and IoT application of molding condition data.

We make the presentation understandable even to those who do not know the plastics manufacturing industry.

Seminar schedule

The seminar will focus on "hands-on experience" as much as possible so that participants can understand various application examples.

We will explain what Aska Company has done to utilize IoT and AI, what we have achieved by continuing to do so, and our thoughts on the future.

※This seminar is expected to last 5 hours including lunch.

The seminar flow shown is an example, and the seminar content is subject to change depending on client needs and conditions.

10:00~ Aska Company's IoT and AI

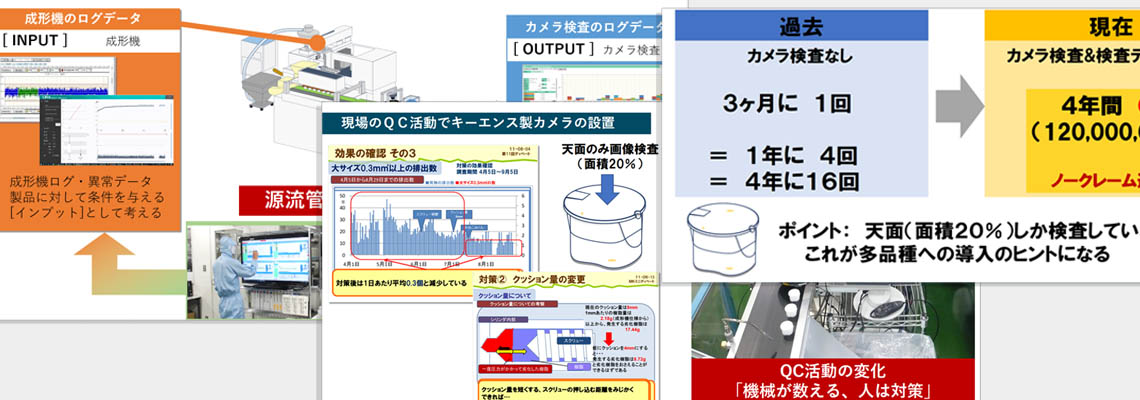

This presentation will introduce the decision-making process that led to the introduction of camera inspection at Aska Company and the case study of reducing foreign matter in QC activities.

We explain the actual success story and the project details of how we conducted the activities by showing materials from that time.

11:10~ Observation of camera inspection at "Head Office S Factory," an unmanned factory at night

You will observe the camera inspection process at the factory.

We will explain how camera inspections are set up and how the data is acquired.

12:00- Lunch (Q&A over a meal)

You can exchange various opinions over a meal.

12:40~ Experience IoT application at "Head Office N Factory," a factory utilizing IoT

You will experience the factory meeting where IoT is being utilized.

The tour will explain what kind of information is being checked and used, and what kind of information is necessary while observing the state of utilization.

13:40~ Optional classroom lecture (selected from 4 types)

Please choose the lecture title that best fits your needs from the following four types of lecture content.

①Practical examples of the initial stage of camera inspection implementation

Have introduced a visual inspection camera but do not know where to start.

We will introduce the operation of image inspection equipment in small and medium-sized manufacturing companies and the system flow up to quality control using data from camera inspection equipment.

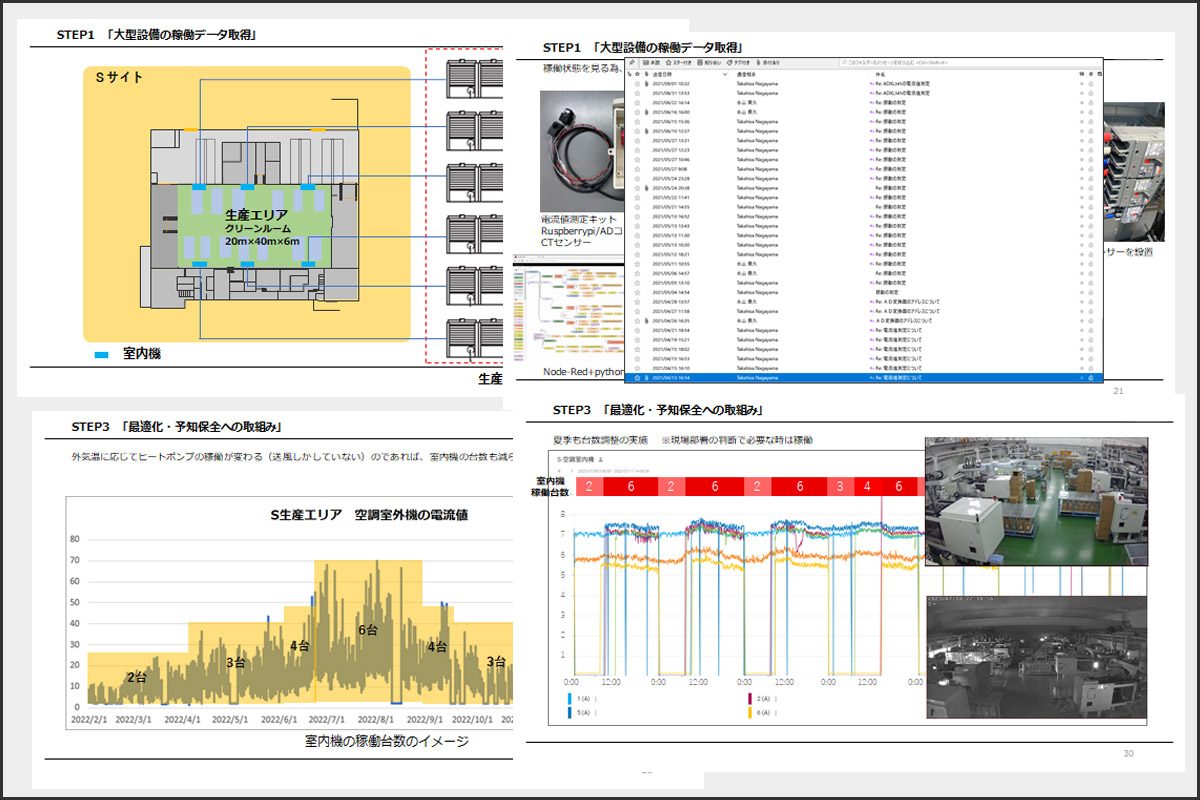

②Examples of sensing data applications

Aska Company continuously monitors log data by installing various sensors such as temperature, humidity, current value, and acceleration to production facilities and infrastructure. We will share with you our success stories of optimization of production facilities and predictive maintenance, including reduction of water and utility costs.

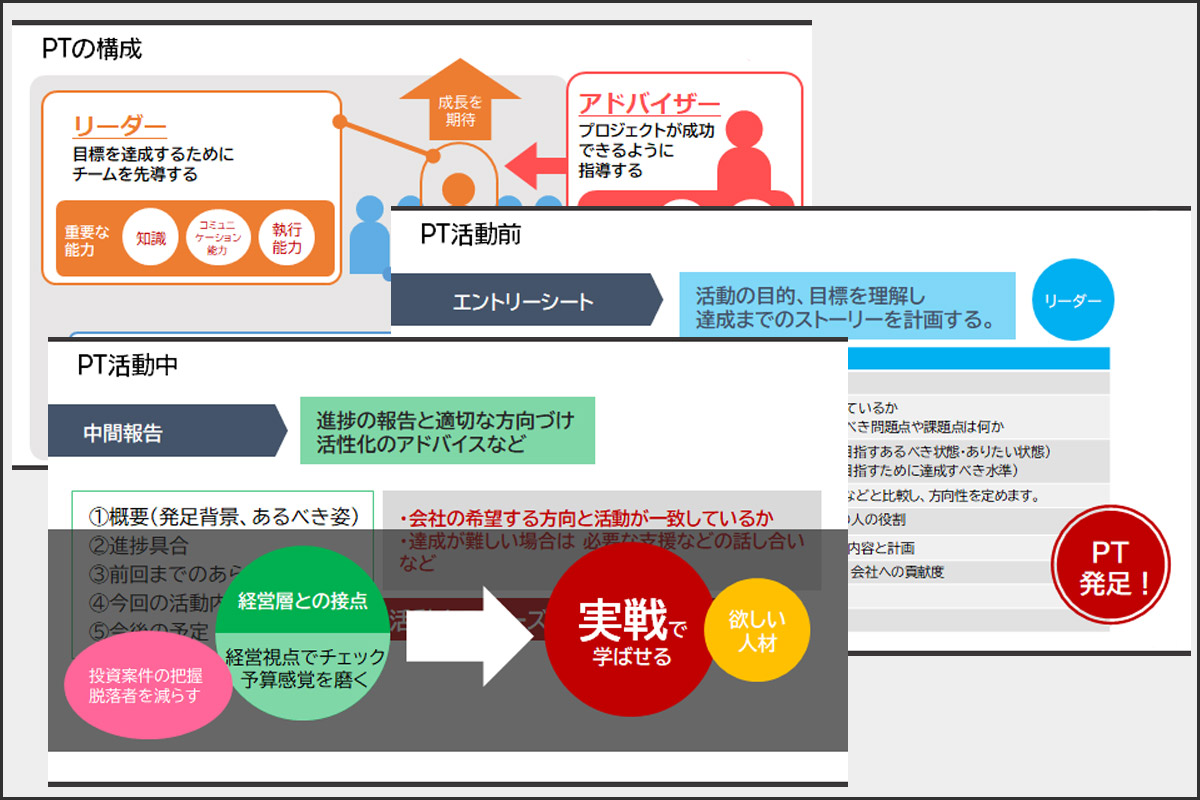

③Explanation of the mechanism for activation of project activities

Through project activities, employees can develop various skills such as communication, logical thinking, and problem-solving abilities by challenging themselves as a group toward an issue.

As a result, the value of people improves.

We always have dozens of groups working on project activities, and we will introduce management methods for the progression and activation of these activities.

④Presentation of project activities and QC circle activities

QC circle activities are bottom-up activities in which employees solve problems by themselves, while project activities are top-down activities in which employees receive special orders from the company to solve problems.

we will introduce some examples of activities conducted at each work site.

14:10~ Break and Q&A

15:00 Finish

From Participating Customers

Seminar fee, number of participants, and location

[Number of Participants]

Open to 1 company only

Up to 4 people

[Fee]

150,000 yen (excluding tax) ※The cost is the same for one course, whether the seminar is for one person or four people.

Lunch will be provided.

[Location]

Head office and factory of Aska Company (Kato City, Hyogo Prefecture)

We will take you on a tour of the production plant at our head factory.

※We will also provide transportation support (Shinkansen to Shin-Kobe and Himeji stations, Itami Airport, etc.).

It will take about 1 hour to get to our company from the station or airport.

There are accommodations such as Route-Inn near our company.

Aska Company Knowledge Park (Kami County, Miyagi Prefecture)

We will take you on a tour of the production plant at Knowledge Park.

※We will also provide transportation support (Furukawa Station Tohoku Shinkansen and Rikuu Higashi Line).

It will take about 30 minutes to get to our company from the station.

There are accommodations nearby.