Offices Full of Individuality

We manufacture our products in Hyogo Prefecture, where Aska Company started its history, and Miyagi Prefecture.

We have two sales offices, one in Osaka and the other is in Tokyo, serving customers in various locations throughout Japan.

Headquarters and Main Plant

The plant is located in Kato City, slightly south of central Hyogo Prefecture.

It is a "Show Factory" consisting of two sites: Site S (completed in 2006) and Site N (completed in 2013).

The factory is on a hill overlooking the Kako River, and lush greenery and nature surround the company. It is only an hour's drive from Osaka, Kobe, and Himeji, making it convenient for getting to cities.

It is near the Takinoyashiro Interchange on the Chugoku Expressway. Osaka International Airport (Itami Airport) can be reached in less than an hour by car, making it easy for visitors from far away to come and visit.

4004 Kotaka, Kato City, Hyogo Prefecture 679-0221, Japan

Phone Number +81 795-48-4323

FAX Number +81 795- 48-9130

Kansai Plant(Aska Craft Co. adjoining)

The Kansai Plant is a factory located in Kato City, Hyogo Prefecture, the same location as the main plant.

There is a production plant with a prototype room and a KY HOUSE with a large ASKA logo opposite the production plant.

Here, we have some department sales, product design, mold/equipment development, and an evaluation center, and we practice agile development from communication with customers to product realization.

We also have a group company, TOMS.Co to manufacture molds, perform mold maintenance, and produce plastic products without people at night.

276-34, Takaoka, Kato City, Hyogo 679-0222, Japan

Phone Number +81 795-48-9900

FAX Number +81 795- 48-4683

Tohoku Plant

In 1978, we were fortunate enough to start operations in Kami-Machi, Kami-Gun, Miyagi Prefecture.

It was a two-plant production system, one in Hyogo Prefecture and the other in Miyagi Prefecture, which was in line with the BCP concept.

When we started operation, since there was no Tohoku Shinkansen line and the Tohoku Expressway had not yet been opened, it was an inconvenient location from Tokyo.

The Tohoku Plant expanded from the first phase to the fourth phase. Tohoku Plant is a cleanliness-controlled factory that serves as a manufacturing base for customers in the Tohoku and Kanto areas, manufacturing plastic products for food, toiletries, stationery, sports, and inspection equipment.

It has a site area of 8,235 square meters and a total floor space of 2,722 square meters.

52 Magosawa Higashizawa, Kami-Cho, Kami-Gun, Miyagi 981-4414, Japan

Phone Number +81 229-67-3883

FAX Number +81 229- 67-6139

Knowledge Park

It was built in 2018 in Gambara Industrial Park, Miyagi Prefecture.

We made this factory be a place where we can share the know-how and knowledge we have gained. We want to contribute to society to improve the productivity of the entire plastics industry with our knowledge.

The building also houses Aska Park, where we can hold various workshops to provide a place for people to grow.

27-7, Aza-Ganbara, Kami-Cho, Kami-Gun, Miyagi 981-4263, Japan

Phone Number +81 229-25-7087

FAX Number +81 229- 25-7085

Osaka Office

207, Sunei Building, 2-7-17 Tenno, Ibaraki, Osaka 567-0876, Japan

FAX Number +81 72- 624-5176

Shinjuku Office

Shinjuku Five One Building 6F, 5-18-16 Shinjuku, Shinjuku-Ku, Tokyo 160-0022, Japan

Phone Number +81 3-6380-2858

FAX Number +81 3- 6380-2885

Group Company

Aska Craft Co.

"A good product starts with a mold."

We established Aska Craft Co. (formerly Toms Co.) in August 1986 as a company to manufacture molds for Aska Company.

In addition to mold production and mold maintenance, we also produce by injection molding, manufacture equipment, and masterbatches.

The office is located in the Aska Company Kansai Plant.

Mold Production and Maintenance

We use special ovens to clean hot runners and equipment-related parts, and we have the support of customers from all over Japan.

Injection Molding

It operates unmanned at night, and a group of highly-skilled technicians, many of whom possess molding technicians (a national qualification),

carry out production under the same quality assurance system as the Aska Company.

Plastic colorants: Masterbatch Production

Aska Connect Co.

Using sensing and big data, we listen to the voices of machines and connect people and machines.

Company Profile

Name Aska Connect Co.

Date of Establishment May 16, 2018

Head Office Address 4004 Kotaka, Kato City, Hyogo 679-0221, Japan

Representative Director Mamiko Hayashi

Director Tsuneo Naganuma

Aska Connect Website

http://askaconnect.co.jp/

※Open in a new tab.

Business Description

1. Planning, design, development, manufacturing, sales, maintenance, operation. Consulting of software peripheral equipment and systems

2. Management and business support

3. Any and all businesses incidental to each of the foregoing

Planning, Designing, and Operation of Software, Peripherals, and Systems

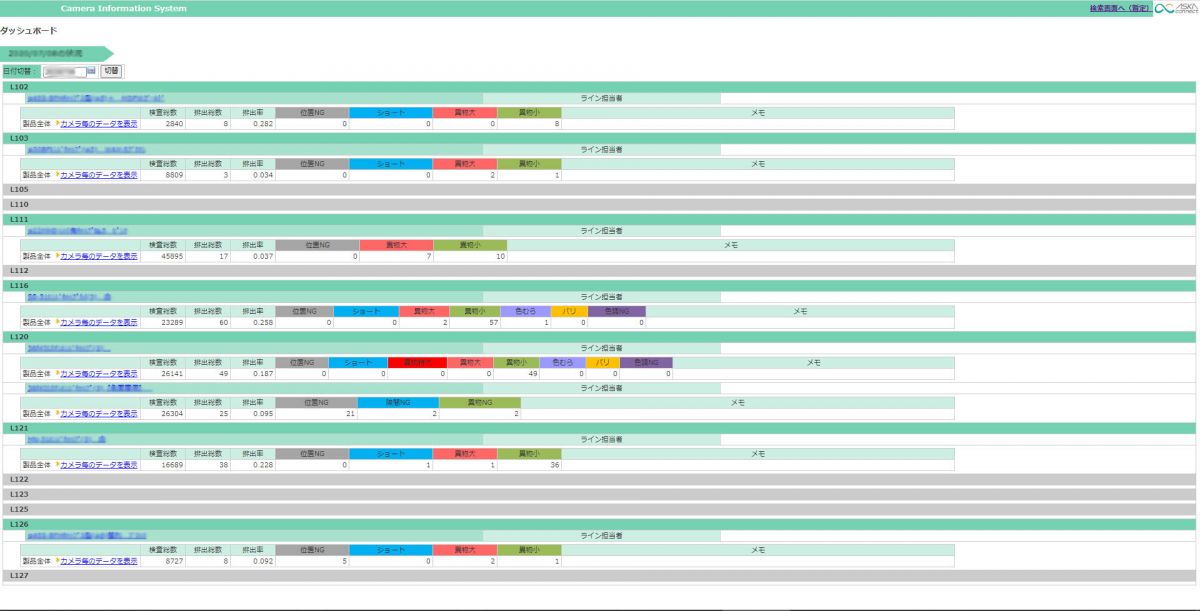

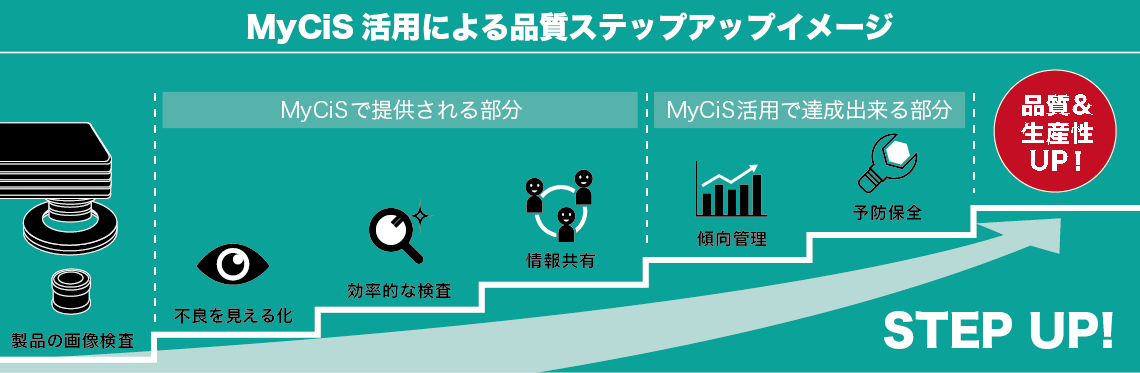

Improve Quality & Productivity 【MyCiS - Camera information System】

Aska Connect's MyCiS utilizes the data obtained from image inspection systems as big data to visualize the production status.

MyCiS makes it easy to realize a smart factory and improve productivity.

To Prevent Breakdowns in Production Equipment 【MyCFM - Clamping Force Monitor】

Aska Connect's MyCFM is a system that visualizes and analyzes the clamping force of molding machines and other equipment

to detect abnormalities in molding machine clamping devices, molds, and products at an early stage.