Even if you have no idea what visual inspection or test cameras are. Do not worry!

You can see and touch the actual visual inspection camera to understand it.

Some of you may be wondering, "How do I handle an inspection camera if I want to automate visual inspection in the factory?

As factory automation (FA) has become the norm, the number of visual inspection lines has also increased considerably.

Even if you want to introduce such a system in your company, there are many things you don't know. For example, how to do it or what kind of system to choose.

Aska Company solved such bewilderment by introducing visual inspection cameras on our own and accumulating know-how.

There are several hurdles in installing cameras, but we feel that once you overcome them, it is not difficult to manage them.

We can help you overcome these hurdles by providing our expertise in introducing and managing inspection cameras in-house.

This seminar is for people who have never heard of or seen a visual inspection camera before.

No programming knowledge or experience is required.

What is a visual inspection camera?

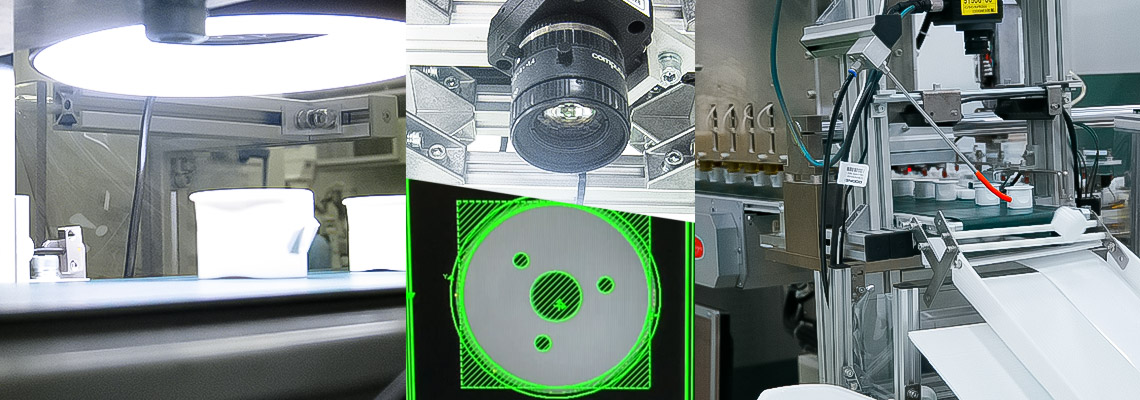

A visual inspection camera is an industrial camera device installed in factories and production lines.

When you hear the word "industrial camera," you may think of something that is "very specialized.

However, it is mainly a camera for photography and a program for inspection.

Smartphones also have a camera for taking pictures and a function for editing images. There is not much difference between the feeling of taking and editing photos with a smartphone and an industrial camera.

Who should attend this seminar?

Our seminar will support you to "install, manage and operate camera inspection in-house" instead of using a contractor to install camera inspection equipment.

This seminar is for beginners who have never introduced visual inspection cameras before or people who want to start using cameras such as

・Those who don't know anything about visual inspection cameras

・Those who want to create a camera inspection line

・Those who want to set up the visual inspection camera by themselves without relying on a vendor

・Those who want to experience the image processing of the visual inspection camera.

・Those who want to gain knowledge about visual inspection cameras easily

Please participate in this seminar as a first step to handling the visual inspection camera which is considered difficult.

Overview of the Seminar

1. Private seminar for one company only

Unlike regular seminars, we hold this seminar only for one company.

Since there is no one from another company, we can customize the content as much as possible.

Also, you can freely ask questions as much as time permits.

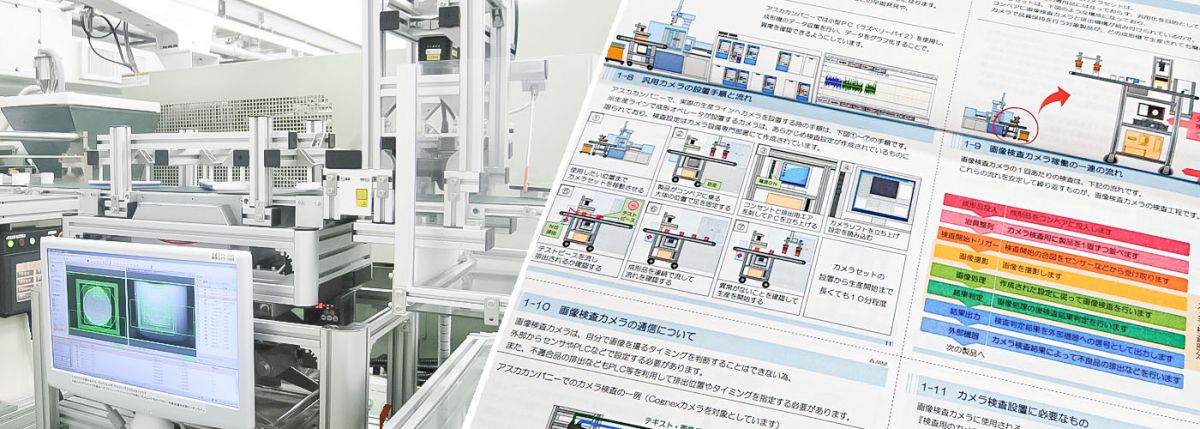

2. You can visit and see our factory which uses visual inspection cameras.

We will explain about visual inspection cameras used in production lines, from the concept of setting up cameras for inspection to how to operate them.

You will also learn how effectively to use the data from the visual inspection camera and utilize the camera as a data acquisition device.

We use a high-performance headset and you can share your questions and answers in the factory.

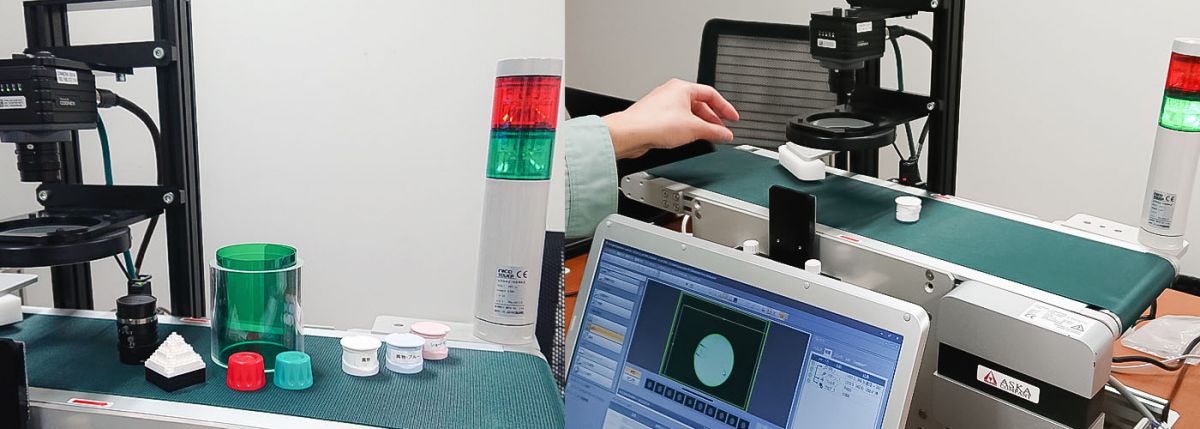

3. Practical training using an actual visual inspection camera

We provide hands-on training using a visual inspection simulator, which is a compact version of actual visual inspection camera equipment.

We will explain how to set up the inspection and what to use it for, based on the products manufactured by Aska Company.

We will carefully explain how to use the software one by one, and together we will create the actual inspection settings.

The inspection settings you make will be applied to the camera equipment and tested for judgment.

Seminar Contents

We hold the seminar using our original materials, including pre-seminar materials and materials we use on the day.

In this seminar, we will tell you the know-how we have accumulated.

This seminar includes all these contents in one day such as

・Factory tour of actual visual inspection cameras and their installation

・How visual inspection cameras are used

・How to use visual inspection cameras effectively

・What you need and how to think about things to set up cameras

・How to select an industrial camera for visual inspection

・How to adjust the camera

・A new approach to quality made possible by IoT x camera inspection data

1. Camera Inspection Line Tour |

|

| ・Visiting the camera inspection line where products are inspected (the factory to be visited may vary depending on the production schedule) ・Introduction of new quality assurance using inspection camera data |

|

2. Lecture: Basic Theory |

|

| ・Basic knowledge in camera inspection ・Experience in our company, etc  |

|

3. Practical Training: Setting |

|

| ・Taking pictures of inspected products using an industrial camera ・Create settings for photographed inspection products ・Checking the quality of the settings using a camera inspection simulator  |

|

※We will work with an image processing camera and software developed by Cognex during the training.

We will explain how to use the software in detail.

The fee, number of participants, and location of the seminar

[Number of Participants]

Open to 1 company only

Up to 3 people

[Fee]

150,000 yen (including tax) ※The cost is the same for one course, whether the seminar is for one person or three people.

Lunch will be provided.

[Location]

Head office and factory of Aska Company (Takino-Cho, Kato City, Hyogo Prefecture)

We will take you on a tour of the production plant at our factory.

※We will also provide transportation support (Shinkansen to Shin-Kobe and Himeji stations, Itami Airport, etc.).

It will take about 1 hour to get to our company from the station or airport.

There are accommodations such as Route-Inn near our company.

Q&A

Even if you bring your products on the day of the seminar, we will not be able to support the exercises.

In Tohoku Factory, we will pick you up at Furukawa station on the Tohoku Shinkansen line. The Tohoku factory is about 15km away and it takes about 30 minutes by car.

Please pay the bank transfer fee.