Thank you for reading Market News.

Aska Company has been developing products using molds called "development molds" in order to speed up the development process.

In this issue, we would like to introduce our own AS Family series molds as an example.

What is Needed in Product Development

In product development, we believe it is necessary to consider and propose product shapes with high-added value.

3D printers are available as tools for shape proposals, but we need to ask ourselves questions such as, "Can this shape fulfill the function of the product? and "What does the surface look like?

To confirm these questions, we need actual molded products made of resin, and for that, we also need molds.

However, it takes two to four months to manufacture a mold, which makes the development period longer and more costly.

Therefore, to speed up product development, we are working on new development models using tools called "development molds."

What are Development Molds?

Development molds are simple molds that enable low-cost product development in a short period of time.

We can make samples with actual molding resins, enabling early proposal of products with shared functions and textures with customers and facilitating smooth development.

Our company uses a common base mold and a mold structure that allows replacement of only the product part, which makes it possible to mold products of different shapes and sizes in a short period of time.

We also have two types of development molds, Agile Mold and Rapid Mold, which are used differently depending on the application of the product.

Two Types of Development Molds

【Agile Mold】

【Agile Mold】

Use of mold product part made of resin modeled by 3D printer

Possible to mold with actual molding resin

【Rapid Mold】

【Rapid Mold】

Metal mold product sections are used to evaluate products

Agile Mold

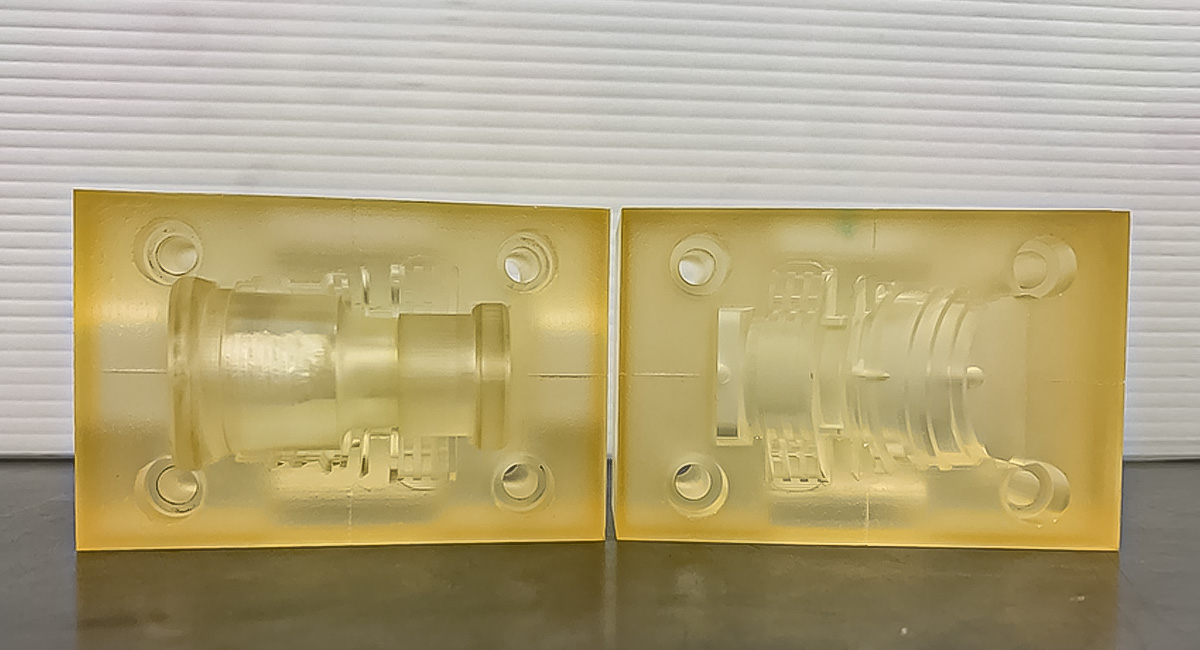

Agile Mold is a resin mold in which the mold product part is manufactured using a 3D printer.

Since the production time is approximately 2 weeks, it is possible to quickly study the optimum shape of the product.

The advantage of Agile Mold is that the product can be molded using molding resin, so it is possible to check the color of the product and, in the case of a spout, conduct welding tests.

The purpose of Agile Mold molded products is to propose shapes to customers.

Agile Mold for AS26.5 Spout

AS26.5 Spout

Rapid Mold

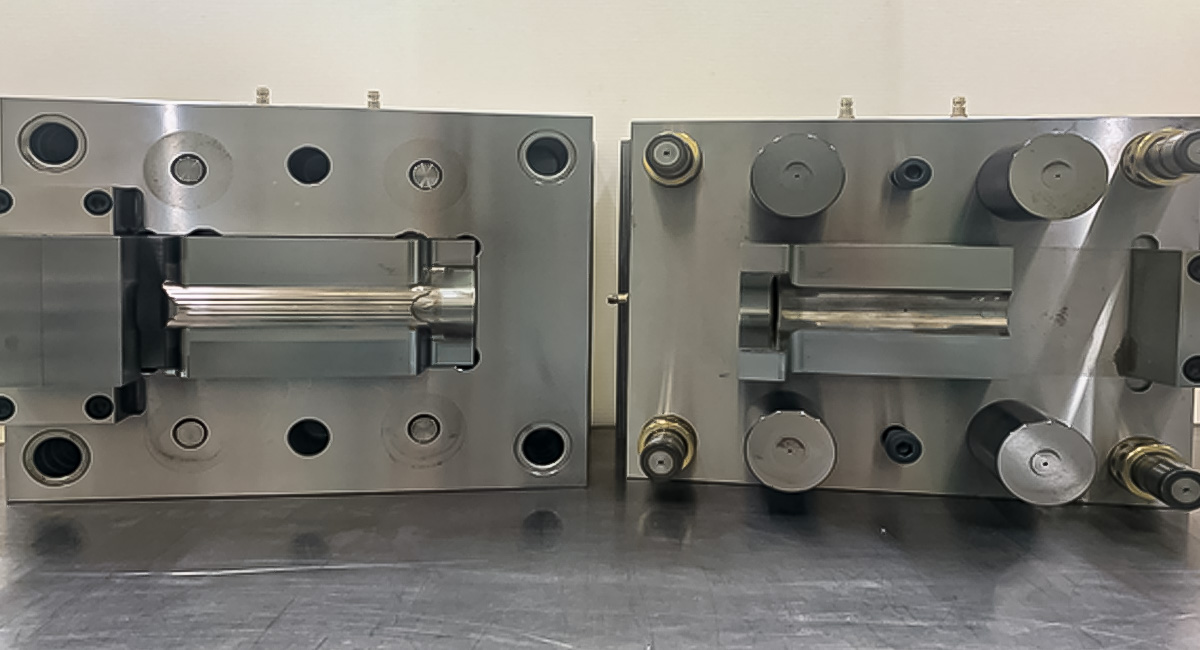

Rapid mold is a mold in which the product part of the mold is made of metal.

Since a common base mold is used, only the product part is manufactured, and the manufacturing time is approximately one month.

The advantage of rapid molding is that the surface condition and dimensions of the product are close to those of the actual molded product.

Applications of rapid mold are for dimensional and functional evaluation and for testing on the customer's production line.

Rapid Mold for AS5

Rapid Mold for AS5 Cap

AS5 Spout and Cap

In this issue, I would like to introduce our development molds.

Manufacturing molds take long time.

Molds for development use, on the other hand, allow for quick verification of the molded product. Therefore, product shape confirmation and product evaluation can be done quickly.

In the future, we would like to use not only the AS Family series but also our customers' projects to create the added value of faster development speed.

Wirter:げっち