At Aska Company, we use digital production as a collaborative activity between man and machine.

At our production site, our dashboard is filled with diverse information in real time.

In order to achieve stable production, the ability of people to read and interpret the various data, and the ability to respond to the conclusions they read and understand, are required.

In other words, "Data Scientists" are indispensable.

"Data Scientist” is a person who makes rational decisions based on data, but many companies may have a problem that data scientists’ knowledge is not used in the field.

One reason for this is that there is a gap in thinking between the “data scientist” and the person in charge of the field.

Data scientists can analyze data and make rational decisions, but they do not have the sensory knowledge and experience of field personnel.

As a result, there were differences in the way analysis results were communicated and perceived, and they were not being communicated well.

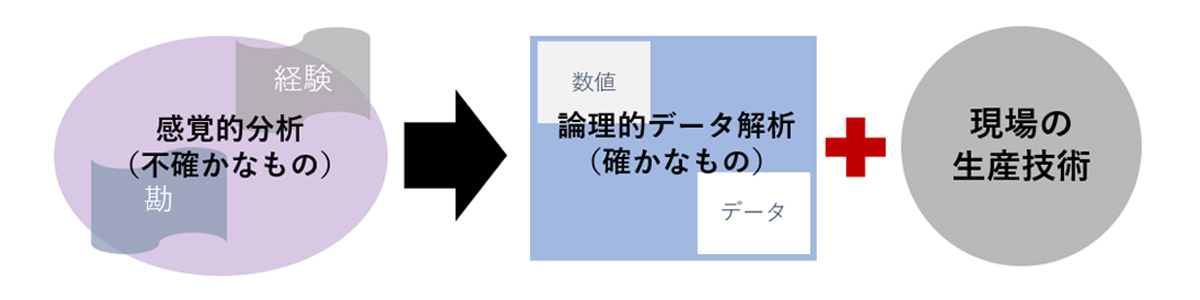

Therefore, the Aska Company came up with the idea of training “on-site scientists” who possess both types of knowledge as a means of eliminating such gaps and arriving at appropriate solutions.

Training of "On-Site Scientists" to analyze data and make improvements.

Aska Company defines a on-site scientist as a person who can logically process data and “create stable production” with his/her own on-site technical skills, and is focusing on the training of on-site scientists.

People have their good points, and machines have their good points.

By converting information from machines into a form that can be understood by people, and by allowing people to carry out logical activities, work that used to rely on the intuition, experience, and other “senses” of on-site personnel can be transformed into improvements based on “logical data analysis. Aska Company's IoT technology is a new way to improve the work process.

Aska Company's IoT aims to expand the capabilities of people through conversations between people and machines.

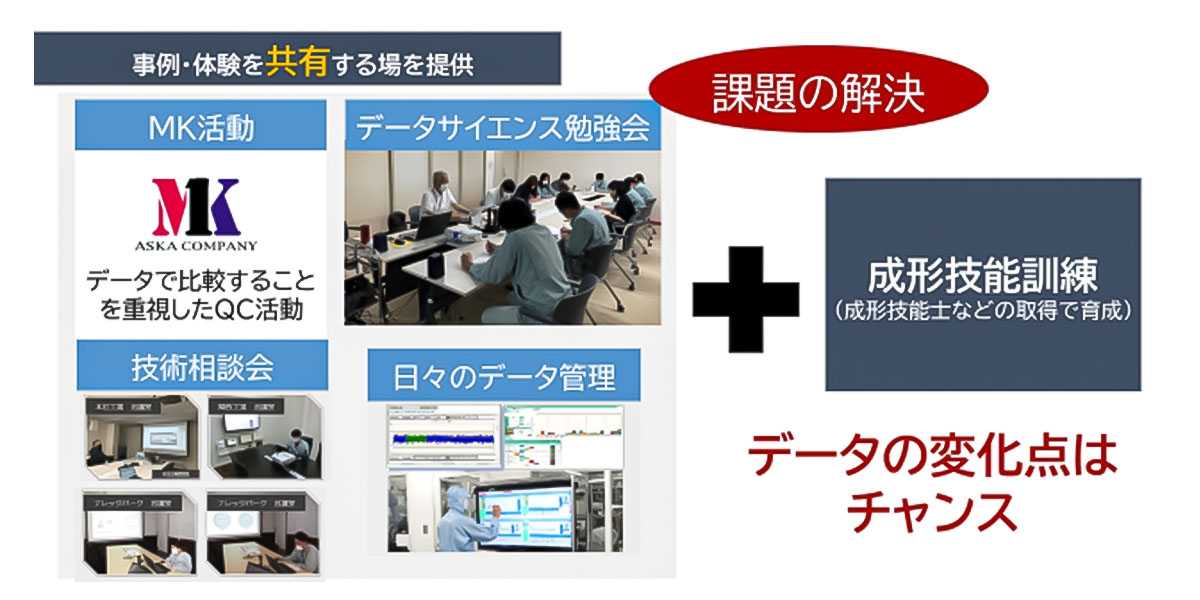

In the field of training on-site scientists, there are various forms of opportunities to share know-how and experiences.

In addition to MK activities (QC circle activities), which have a history of more than 50 years, we provide opportunities for “education” in various forms, such as practical daily data management, dedicated study sessions, and technical consultation sessions by inviting university lecturers from outside.

Toward Open Factories and Safe Manufacturing

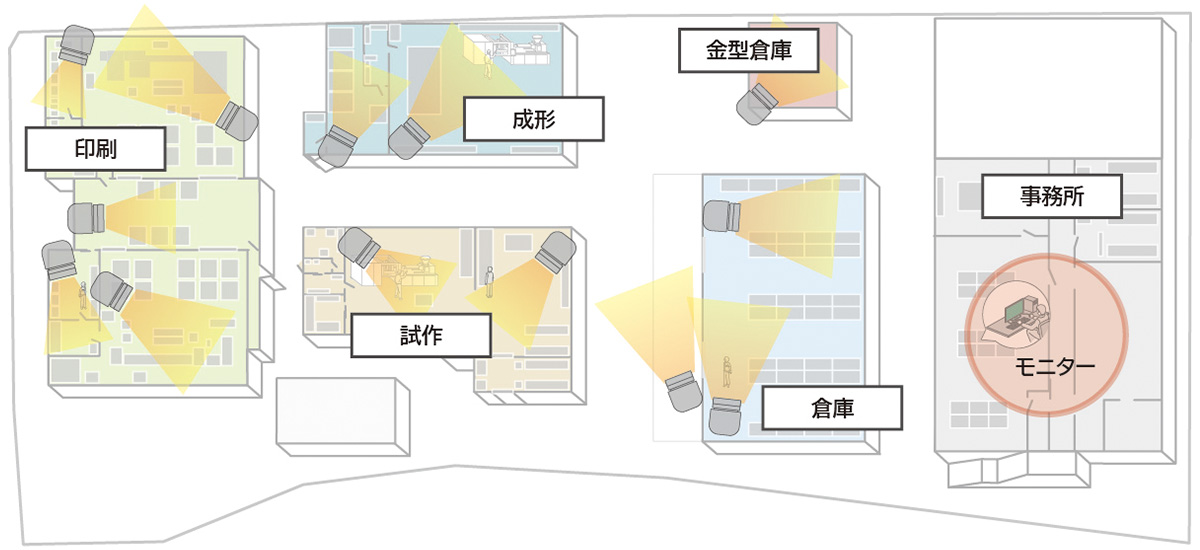

Aska Company has two production facilities, one in Hyogo Prefecture and the other in Miyagi Prefecture.

The Kansai factory in Hyogo Prefecture, where the company was founded, has five separate buildings, each of which must be entered in order to see what is going on inside, making it unsuitable for factory tours.

In order to ensure both “open factory” and “factory safety,” we decided to install 14 network cameras in the factory.

The images of each building can be viewed from the office, so the inside of the factory can be monitored without the need to enter the factory.

Furthermore, customers can see what is going on inside the factory in real time from the office area, enabling effective factory operation in terms of infection control.

You are welcome to visit our booth in conjunction with our seminar!

Introduction of Aska Company's Seminars

The Aska Company has set “contribution to productivity improvement in the plastics industry” as its management goal and shares its know-how through seminars. We have received repeat attendance from other companies in the industry and major manufacturers, and recently, we have received an increasing number of requests for lectures from overseas customers and outside parties.

We look forward to your participation!

『アスカカンパニーのセミナー』

様々な技術・技能・デジタル化・機器の活用・DXなど問題を解決できる体験型セミナー

Seminars Simplified List

| Digital Improvement Activities and Human Resource Development |

Nighttime Unmanned Factory | Appearance Inspection Camera | Human Resource Development | |

| Classification | Experiential Seminars | Experiential Seminars | Workshop | Experiential Seminars |

| Policy | Site Improvement | Site Improvement | Site Improvement | Culture and Organization |

| Subjects of the course | Management/Planning/Production/Manufacturing | Management/Planning/Production/Manufacturing | Management/Planning/Production/Manufacturing | Management |

| Time | 5H | 5H | 7H | 5H |

| Number of Participants | 4 people | 4 people | 3 people | 4 people |

| Fee | 150,000 yen (excluding tax) | 150,000 yen (excluding tax) | 150,000 yen (excluding tax) | 150,000 yen (excluding tax) |

| Contents | IoT and AI applications/initiatives by field scientists and others/selective classroom lectures (4 items) | How to proceed and practice unmanned nighttime operations Optional classroom lecture (4 items) |

Experience setting up a visual inspection camera | Target management and evaluation system and construction flow |

| Past Results | 20 times / 2 times hosted by outside organizations | 22 times / 2 times hosted by outside organizations | 28 times / 23 times hosted by outside organizations | 1 |