"The Management" function evolved from the previous year

In the February 2021 issue of ASKA MARKET NEWS No. 309, we introduced a time management application for mold changes.

Now, we would like to introduce our evolved mold change application.

Mold Change Operation

Mold changing is a process that requires human skill, teamwork, and planning.

Time management of the mold change process is essential for the efficient production of a wide variety of products.

Building a Solid Mold Change Operation

By planning"When", "Who", "With whom", and "How long a mold change will take," it is possible to confirm plans and give instructions and orders.

We use the app to check records, and it gives us feedback after the setup is finished and to manage numerical values onsite.

It is possible to numerically manage mold change work, which tends to be performed by a single person.

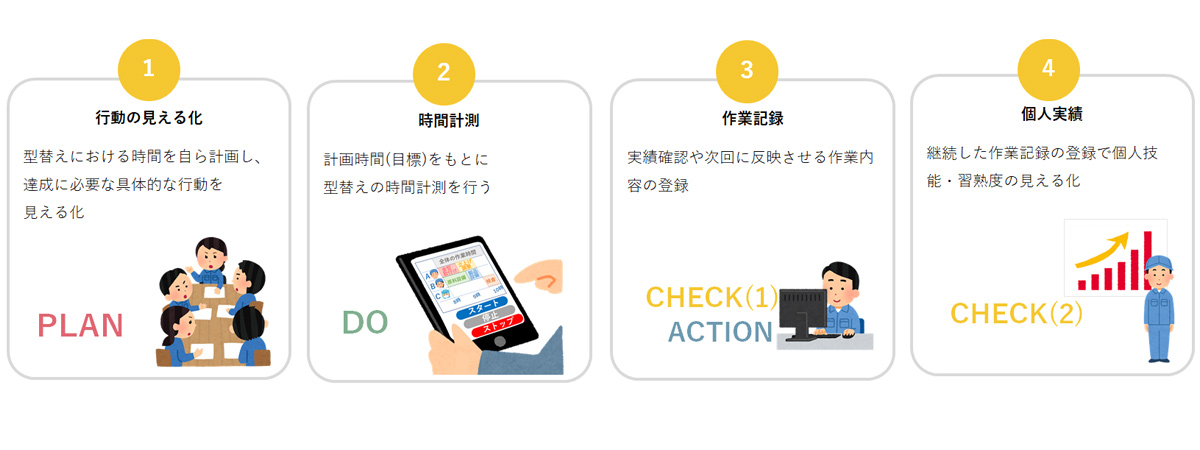

4 STEP for Mold Change Application

Using retyping application creates a mechanism to rotate the PDCA cycle, thereby increasing operational efficiency.

In addition, to encourage productive behavior, Aska Company emphasizes the following four points.

☑Set Detailed Goals

By setting a target time for each task, you can learn which tasks you are not good at and take time-conscious actions.

Of course, producing non-conforming products is meaningless even if the time is fast.

Therefore, we also check to see if we are producing compliant products.

☑Teamwork

They complement each other's abilities and cooperate to enhance teamwork and improve work efficiency, and then they achieve the goal.

☑Time to Reflect

Create time for reflection by comparing targets and actual results during morning and evening meetings

to identify the degree of achievement and factors that led to exceeding the target time.

☑Visualization of Individual Skills

Improvement of worker skills is directly related to mold change time.

Visualization of workers' skills and proficiency levels will lead to work motivation.

【Examples】What we visualize in time management application

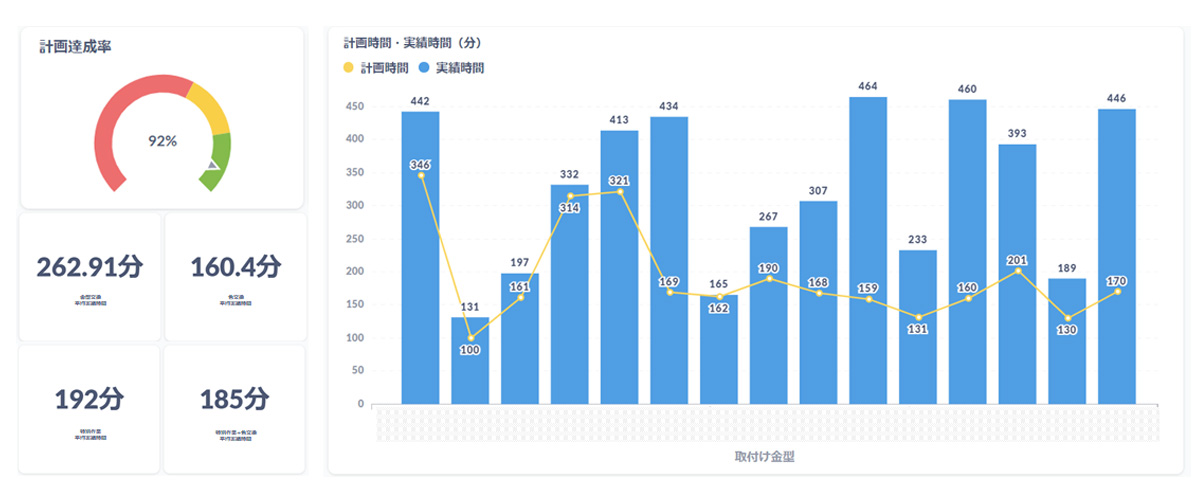

Aska Company manages data by dividing it into "results by each factory," "results by mold," and "individual results."

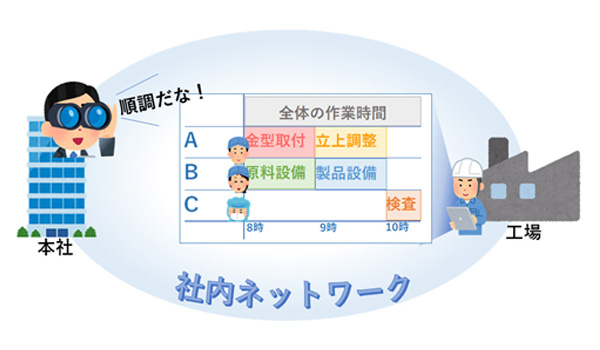

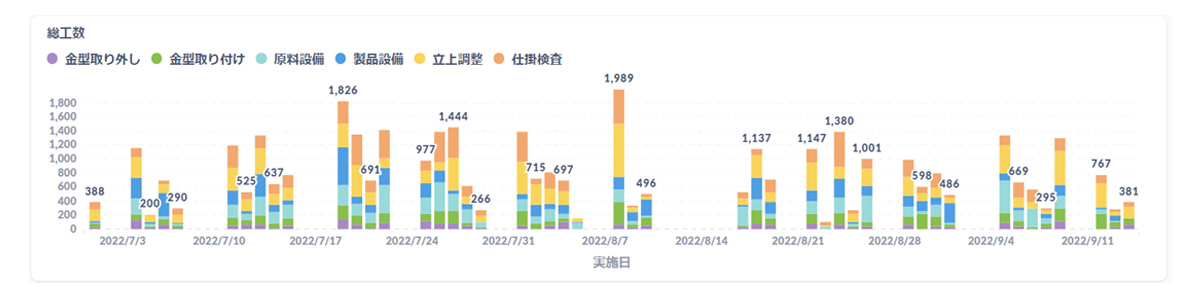

>Results by Each Factory

The "results by each factory" show the percentage of mold changeover time achieved at each plant and the time spent on each operation by work classification.

Although we have a total of five production sites in Hyogo and Miyagi prefectures, we can view the movements of each plant from remote locations.

>Results by Mold

In the "results by mold," you can look back on past mold change operation times to grasp mold characteristics,

such as points to be careful about in the subsequent mold change and to prepare for time-consuming operations before we start it.

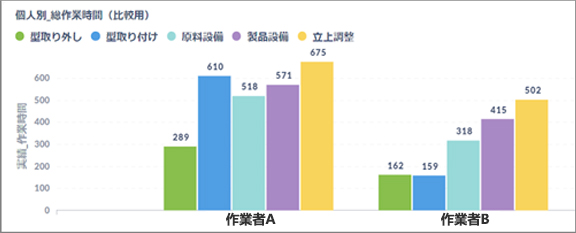

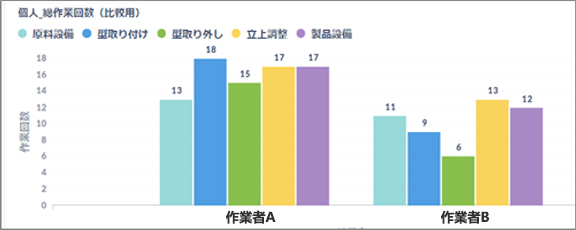

>Individual Results

In the "Individual Results," you can compare the number of times and hours worked by individuals.

Although it is not easy to visualize skills, it would be possible to measure the degree of growth by comparing the percentage of goals achieved, time spent on tasks, and current and past performance.

Comparison of the number of operations

Work Time Comparison