Digitization and IoT

At Aska Company, we continue to promote digitalization.

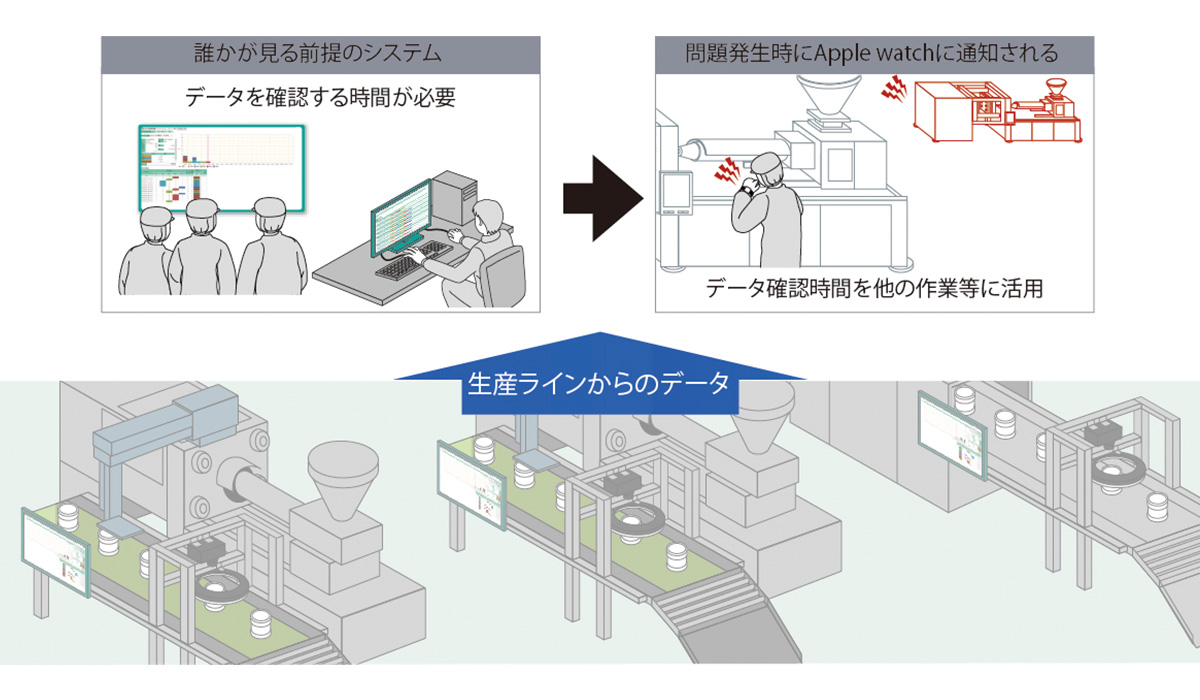

The company's sensors and devices are connected to the network through the IoT, and employees can see data from anywhere.

As we understand the benefits of digital, we get actively networked.

We can check and review the data from production lines and check the operating status and abnormalities of factory infrastructure from afar.

Networking has helped bridge the distance and increased the time that we can spend on review.

The Aska Company's digitalization challenge has lasted more than 20 years, including the parts that are undisclosed to the public, and these many years of digitalization have enabled us to take advantage of skills that used to be tied to individual and regional areas.

But when we are surrounded by so much data, which ones do we need?

That is where "LMK" comes in.

What is LMK?

LMK stands for "Let me know."

The LMK is a system that "automatically notifies you of its status."

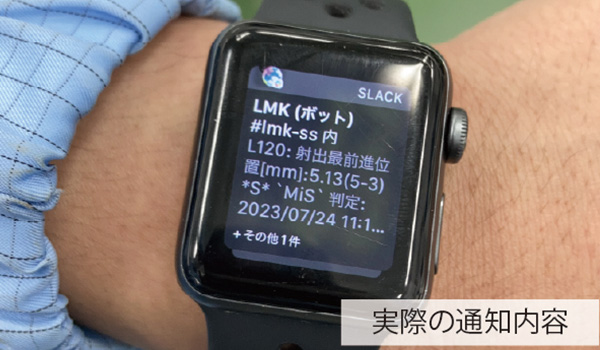

If certain conditions are exceeded, the Apple Watch (and other devices) worn by workers receive the information. Workers can see the problem on the spot.

We use a communication tool called Slack for notifications.

The general-purpose tool provides good communication stability and saves time and effort in creating, installing, and operating applications.

In the past, the use of digital technology required operators to see the data from camera inspections on a monitor and to check the molding machine data for any abnormalities.

Since LMK automatically notifies us of its status, we no longer need to check the data on the monitor and can make better use of our time.

LMK Structure and Concept

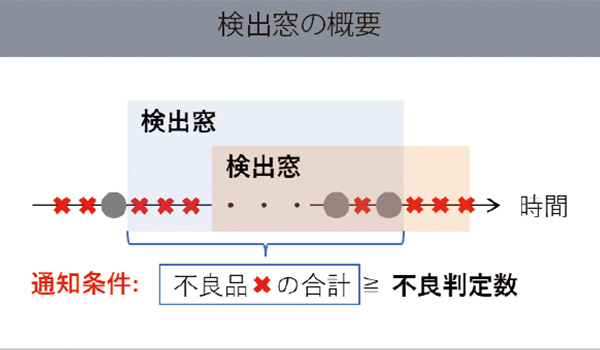

LMK is a notification system, but there is a setting for that notification.

We set the notification by measuring the number of defects within a certain period.

(This certain period is called the "detection window.

The setting is not based on the number of defects but rather on the percentage of defects within a certain period.

In addition, we utilize "decision trees," a machine learning algorithm, to allow for a certain degree of flexibility in detecting defects as people would think. The decision tree is a method of classifying a large amount of data under certain conditions and then classifying the data again to derive what is highly likely to occur from the original data.

The algorithms allow for detection and operation that are similar to the results of human verification.

Based on the history of data operation up to now, we provide various setting targets and functions such as "for each molding machine and product" or "for all molding machines in one production plant" while providing the operation method without any settings.

That helps operators find their operation methods on their initiative.

We also use a communication tool called Slack, which allows us to record the results of notifications by replying to it and recording the details of the response.

Various Know-How

We have been promoting the networking of devices, data acquisition, and data utilization through IoT, and at the same time, we have been discussing and trying to figure out "how to operate" and have accumulated know-how in this area.

Since data can tell us many things, we tend to acquire a lot of data, but sometimes only a little data is necessary.

If you have any doubts about where to start, what to do, or how to check data in IoT and DX, please feel free to ask us at our seminars, where we can provide you with various know-how.

-

-

Digital Transformation Top Seminar

What can we do with Digital Transformation? How do we get started? Digital Transformaiton Top Seminar【"Encouragement of Digital Transformation" for Small and Medium-Sized Manufacturing Companies】 Seminar on "Getting Started with Digital Transformation" for Small and Medium Business Owners! These days, not a day goes by that we don't hear the keyword "Digital Transformation." For more than 10years, Aska Company has been working to improve quality by feeding back data from the manufacturing floor into our daily operations. We want to share some of the "Digital Transformation Tips" that we have learned from our experience, including various effects that we ...