What is the Technology Advancement Award from the Society of Plastic Molding and Processing Engineers?

What is the Technology Advancement Award?

It is the awards that the Japan Society of Plastic Molding and Processing aims to promote technological progress in the plastic molding field and award highly original technologies that contribute to the advancement of this field, along with expectations for the future.

Tsuneo Naganuma and Professor Hashimoto of Graduate School of Information Science and Technology, Tohoku University, presented

"Development of Anomaly Detection Technology Leading to Predictive Maintenance of Injection Molding Machine Mold Clamping System" and received the 9th Technical Progress Award.

An article about the award will be published in the October issue of the Journal of the Society of Plastic Molding and Processing Engineers.

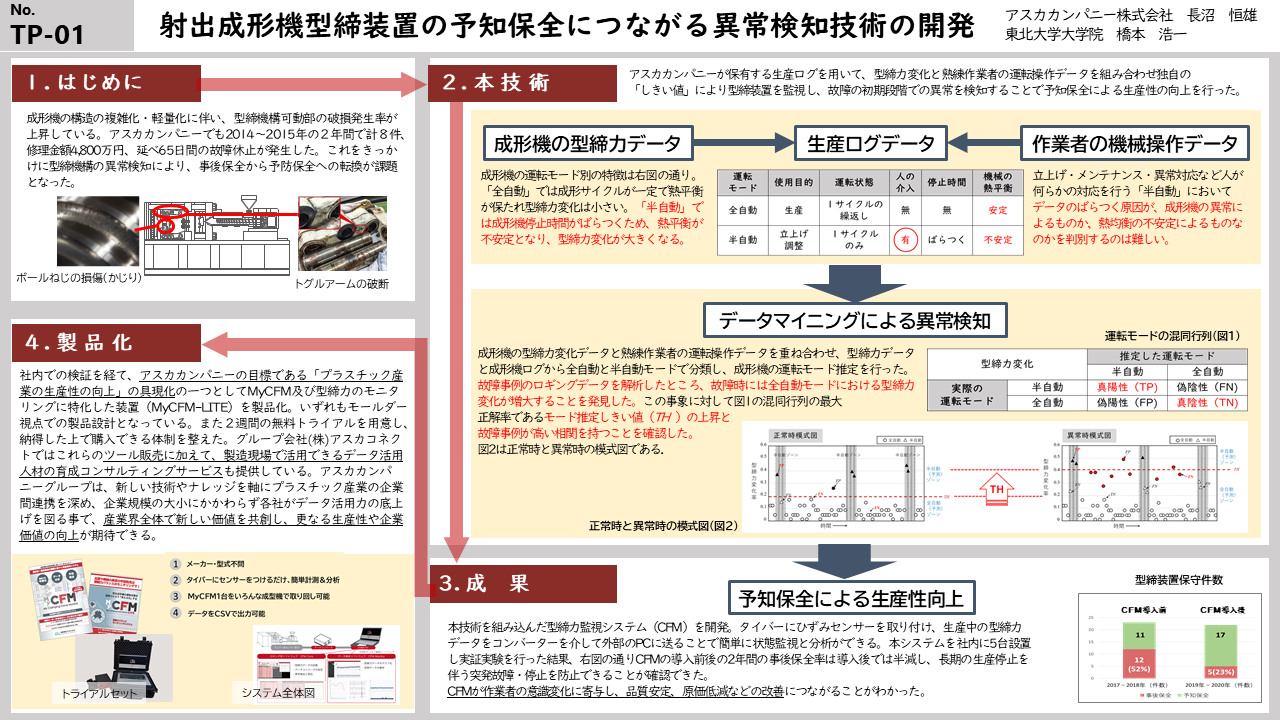

Title: Development of Anomaly Detection for Predictive Maintenance of Injection Molding Machine Clamping Equipment

Injection molding machines are used to process and produce plastic products from plastic raw materials.

The mechanism of the injection molding machine includes a "mold clamping device" that opens and closes the mold and maintains the mold clamping force.

(The maximum mold clamping force of our machines is 350 tons.)

At Aska Company, we have had cases where production has been halted for a long due to malfunction of the mold clamping device, even on new injection molding machines.

The malfunction of the mold clamping device affects not only the customer but also the entire supply chain.

Since the molding machine manufacturer is not a party to the problem, the responsibility for supplying the product rests with the Aska Company.

To break out of this situation, Tsuneo Naganuma thought, "The Aska Company, which uses molding machines, must have the technology to predict machine failures," and began research.

The mold clamping force data in operation at our factory is big data, with each molding machine producing thousands of shots every day.

We have developed a technology that can predict failures by performing various processes on these big data and implemented it in our factories.

We were also able to obtain a patent for this technology.

Aska Company is creating an environment that is easy for people to read and understand by processing data on the facts conveyed by the molding machine.

It is truly a "collaboration between man and machine.

The details of our research are as follows.

※Click to enlarge.

The award was also introduced in the Graduate School of Information Science and Technology, Tohoku University.

Aska Company also conducts paid seminars based on the know-how we have cultivated in plastic molding.

If you have any questions, please feel free to ask us.

What can we do with Digital Transformation? How do we get started? Digital Transformaiton Top Seminar【"Encouragement of Digital Transformation" for Small and Medium-Sized Manufacturing Companies】 Seminar on "Getting Started with Digital Transformation" for Small and Medium Business Owners! These days, not a day goes by that we don't hear the keyword "Digital Transformation." For more than 10years, Aska Company has been working to improve quality by feeding back data from the manufacturing floor into our daily operations. We want to share some of the "Digital Transformation Tips" that we have learned from our experience, including various effects that we ...

Digital Transformation Top Seminar

Molding Skill Seminar