For your safety!

This time, we would like to introduce "Kittarou," a product that contributes to "safety" and "occupational accident prevention" for dangerous work such as cutting plastic molded products. In the past, our company used cutters to cut products, and there was a risk of accidentally cutting one's hand. Kittarou was developed as part of our MK Activity® to cut products more safely. We will introduce what kind of functions and safety devices are provided in Kittarou while looking at the development process.

How Kittarou was developed

Before the development of Kittarou, we used to cut dozens of products a day to inspect whether the products were proper. Cutting with a cutter was a hard and forceful operation, and it was also dangerous work that could result in accidental cuts to the hands. To eliminate danger, we developed the concept of a device that can cut with ease and with a low risk of injury through MK Activity®. Then, thinking that our company's problems must be the same as those of other companies in our industry, we started selling Kittarou. And now, our customers highly appreciate Kittarou's safety features as they are good in preventing industrial accidents.

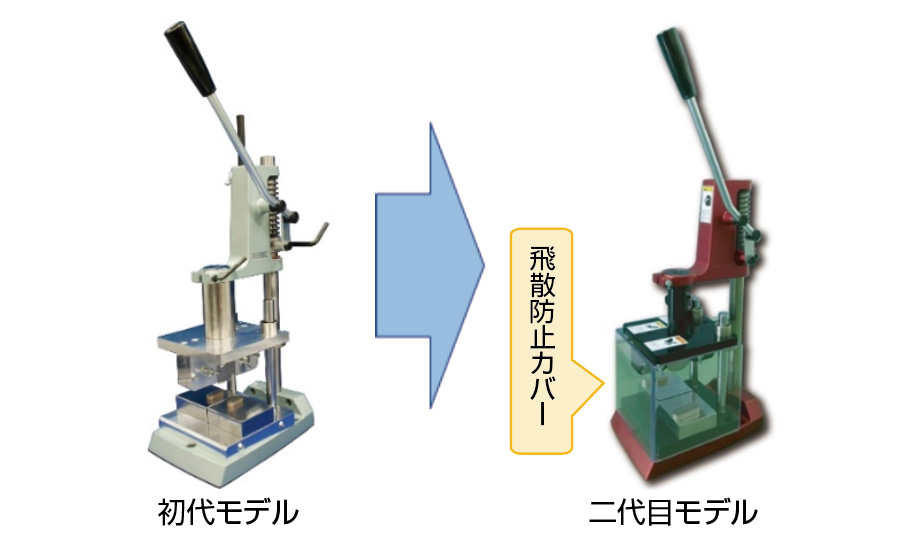

In the early models of Kittarou

The structure consists of placing the molded product on the cutting stage, positioning it with a magnetic jig, and lowering the circular blade with a lever for cutting. All the user has to do is lower the lever, so there is no danger of cutting the hand. Also, since cutting can be done easily by the principle of leverage, there is no need for excessive force.

In the second generation model

We added the shatterproof cover to prevent splattering of cut molded parts.

The shatterproof cover eliminates the risk of debris getting into the eyes.

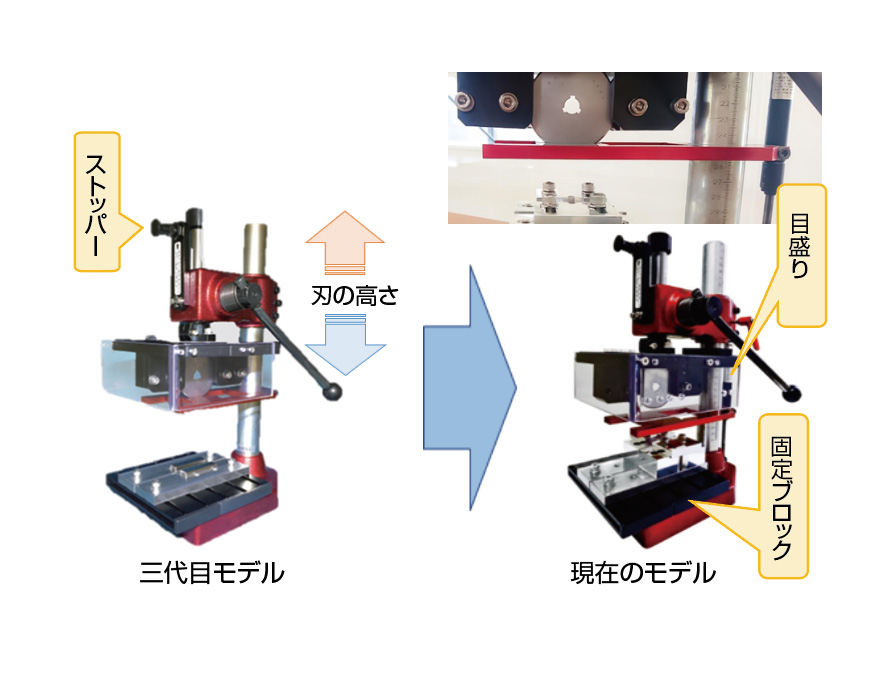

In the third generation model

It was possible to adjust the height of the blade (cutting position) to match the products. The lever has been lowered to a more compact position to allow work while seated. We added the stopper to prevent hand entrapment. We had to use the right hand to cut, and with the left hand, we released the stopper, which requires a two-handed. We could raise and lower the shatterproof by the height of the blade to improve workability in fixing the products.

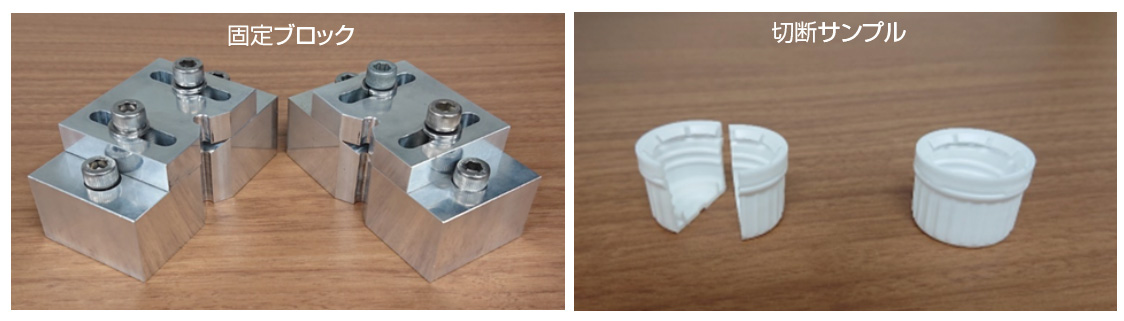

In the current model

We have changed the jig for fixing products to a "fixing box" with high bolting versatility. Thus, products that can be fixed have increased. In addition, we have added a scale to the shaft to allow the blade height to be the same for each product.

Next generation model

We are currently developing the next-generation model of Kittarou based on feedback from customers and within the company. The details are a secret, but we are planning a model change that will mainly contribute to more accurate and shorter setting times. We are planning to sell the product in the fall of 2022. As described above, Kittarou, which was born from MK Activity®, is evolving while improving usability and safety based on feedback from our customers and our company. If you have any questions or concerns about cutting plastic, please feel free to ask us for a free sample cutting evaluation or to borrow a demo machine.