Thank you for reading Market News.

Recently, we have been receiving a lot of questions about the "AS Spout Series," which we have been introducing, such as "Can we use it with ice cream? Is there any problem if we want to store it frozen?

We have received many such questions about "freezing," so we decided to evaluate the product by freezing it.

Functional Evaluation of Frozen Spouts

Recently, we have been receiving a lot of questions about the "AS Spout Series," which we have been introducing, such as "Can we use it with ice cream? Is there any problem if we want to store it frozen?

We have received many such questions about "freezing," so we decided to evaluate the product by freezing it.

To ensure that there is no leakage of the contents, it is necessary to guarantee airtightness.

There are several methods to evaluate airtightness, but we evaluate it using a pressurization test.

To compare and evaluate with AS spout, we purchase samples (market products) that are compatible with the freezer and use them for measurement evaluation.

Our measurement targets are

・AS9.5 Spout (inner diameter: approximately 9.5 mm)

・AS16 spout (inner diameter: approximately φ16mm)

We prepared three samples for comparison.

(We will refrain from giving details, but these products are for ice cream and frozen beverages.)

Airtightness Test Evaluation Details

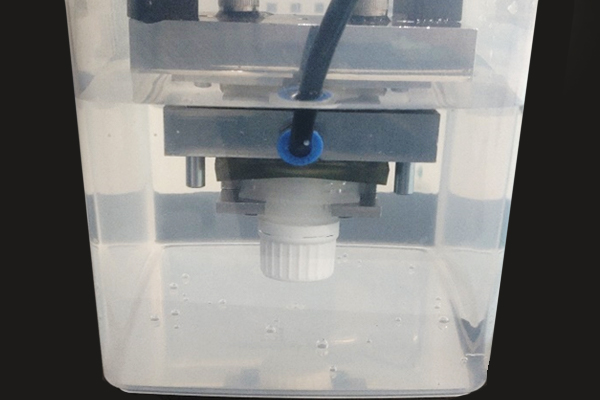

Evaluation Item: Airtight (Pressurized)

- Stand the sample with spout and cap mated at room temperature (23°C) and freezing (-18°C).

- Set the sample on the jig.

- Pressurize at 0.3 MPa for 10 seconds and check for airtight leakage.

Result

| Room Temperature 23℃ | |||||

| Level | Sample A | Sample B | Sample C | AS9.5 | AS16 |

| 1 | ○ | ○ | ○ | ○ | ○ |

| 2 | ○ | ○ | ○ | ○ | ○ |

| 3 | - | - | - | ○ | ○ |

| 4 | - | - | - | ○ | ○ |

| 5 | - | - | - | ○ | ○ |

〈Result〉

・All leak-proof.

| Freezing -18℃ | |||||

| Level | Sample A | Sample B | Sample C | AS9.5 | AS16 |

| 1 | × | ○ | × | ○ | ○ |

| 2 | ○ | ○ | × | ○ | ○ |

| 3 | - | - | - | ○ | ○ |

| 4 | - | - | - | ○ | ○ |

| 5 | - | - | - | ○ | ○ |

・Airtight leakage occurred in marketed products A and C

Since the content of marketed product A is ice cream and almost solid, it is assumed that leakage of the content in the market is unlikely to occur even if the airtightness is slightly low (confirmed by maintaining airtightness up to 0.25 MPa).

・Market product C leaked at 0.05 MPa (Market product C is imported from overseas and contains many foreign objects and burrs.)

The evaluation results show that AS spouts are more airtight than freezer-compatible samples.

Is the Strength Enough when Frozen?

When frozen, there is a concern that the spout may crack when the product is dropped.

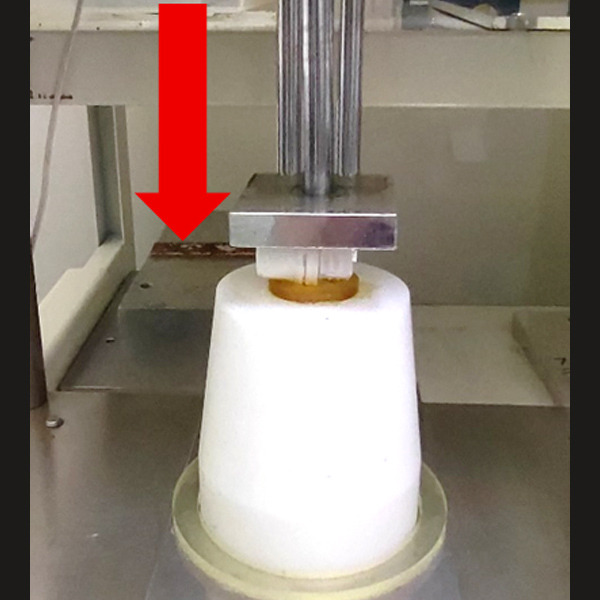

As for cracking strength, Aska Company can determine the 50% impact fracture energy using the "S-Gauge (fracture strength tester)," developed in-house!

-

-

Contract Measurement Service

続きを見る

S-Gauge evaluates fracture strength using a 50% fracture energy (J: joule).

※The 50% fracture energy is a method for determining the value at which a workpiece will crack with approximately 50% probability when a fixed value of fracture energy is applied to the measured workpiece.

Impact Test Evaluation Details

- Stand the sample with spout and cap mated at room temperature (23°C) and freezing (-18°C).

- Set the sample in the impact tester (see the Right figure)

- Drop a 1,000 g weight on the sample and measure the 50% fracture height (cm) and 50% fracture energy (J).

What is 50% Breakdown Height (cm)?

Height at which the sample is expected to be cracked with 50% probability (limit of measurement: 77.5 cm).

What is 50% Fracture Energy (J)?

The energy at which a sample is expected to be cracked with a probability of 50% (measurement limit: 7.6 J)

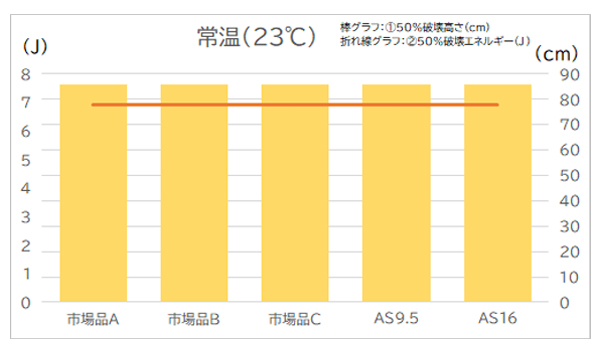

Result

| Room Temperature 23℃ | |||||

| Level | Sample A | Sample B | Sample C | AS9.5 | AS16 |

| 50% Breakdown Height (cm) | 77.5 | 77.5 | 77.5 | 77.5 | 77.5 |

| 50% Fracture Energy (J) | 7.6 | 7.6 | 7.6 | 7.6 | 7.6 |

- Not all cracked, but deformed.

- Not cracked, but marketed product A had 2 broken at the tamper area.

- AS9.5 has one bridge breakage.

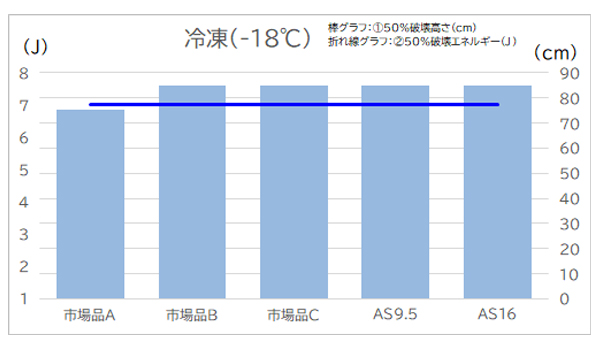

| Freezeing -18℃ | |||||

| Level | Sample A | Sample B | Sample C | AS9.5 | AS16 |

| 50% Breakdown Height (cm) | 70.0 | 77.5 | 77.5 | 77.5 | 77.5 |

| 50%Fracture Energy (J) | 6.9 | 7.6 | 7.6 | 7.6 | 7.6 |

- All deformed.

- Cracks occurred in market product A.

- No cracks, but bridges were broken on market Products B, C, and AS9.5

- No cracking and no tamper breakage on AS16

As a result, we found that the AS spout has the same strength as market products that can be frozen.

We have introduced our measurement method and the results from the viewpoint of whether the AS Spout can be used for frozen.

If you are considering the use of AS Spout for freezing, we will provide you with samples, and we would like you to consider adopting them after another evaluation.