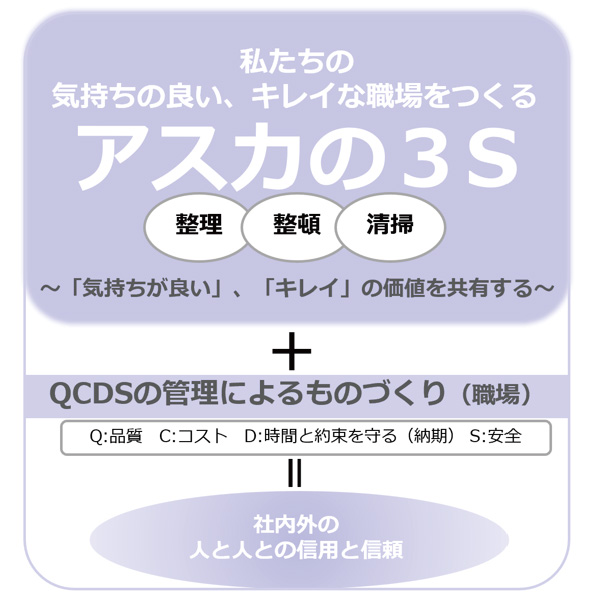

Purpose of 3S

"3S" is a collective term for these three elements: Seiri (Sorting), Seiton (Tidying), and Seisou (Cleaning).

The purpose of 3S at Aska Company is "to create a pleasant and clean workplace for us."

Each individual has a different sense of what a "pleasant and clean workplace" means.

Therefore, we share the "basic rules handed down by the Aska Company" to align our values.

Specific rules include the following

- Greetings in a loud voice.

- Vertical, right angle, no crookedness.

- White color base color, considerations not to make it dirty.

- Do not place items directly on the floor.

- Keep postings to a minimum.

- Use the Aska Company logo correctly.

Another means of sharing value is "QCDS management in the workplace.

We believe that by exploring the details of QCDS management at each workplace, we can share values in a concrete and easy-to-understand manner.

In this way, Aska Company believes that refining the 3Ss helps deepen the bonds between people inside and outside the company.

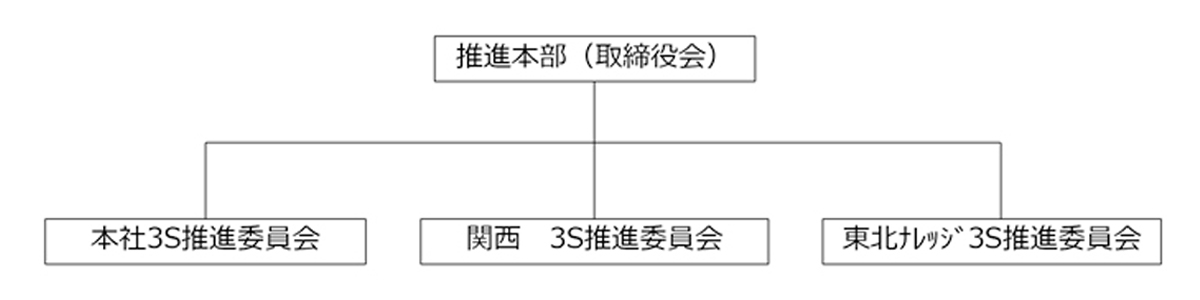

3S Promotion Committee

Aska Company has established the "3S Promotion Committee" to promote 3S. We are pleased to introduce the renewed structure of the committee as of January 2022.

The 3S Promotion Division is headed by the Board of Directors. 3S Promotion Committees have been established at each of the three sites: the Head Office Factory, Kansai Factory, and Knowledge & Tohoku Factory.

The term of office of the committee chairperson is two years, and committee meetings are held once a month at each site. Furthermore, once a quarter, a joint committee meeting will be held between the promotion headquarters and the chairpersons of each site to share and brush up on the content of the committee.

3S Promotion Activities

Aska Company conducts monthly 3S promotion activities at each workplace and issues an activity report.

In this issue, we would like to introduce the activities of the PL Center at the main factory for November 2021.

The PL Center is a quality control department. It is independent of the production organization and assures the quality of products.

■Activities

"Cleaning and filling in gaps in the inspection room doors."

■Reason for Activity

"We had to fill in the gap from an insect control standpoint."

"The door had been closed for a long time, and we had not cleaned there."

■After Activity

- We cleaned up by removing dust!

- We used aluminum tape to fill in the gaps to reduce the risk of insect infestation!

- We inserted a nylon string between the tape to cut off the aluminum tape so that we can quickly remove it in case of emergency!

We are working on 3S in each workplace in this way.

Aska Company will continue to work on 3S daily, and by continuing to refine it, we will deepen the bond with everyone.