Many companies may consider factory automation, labor saving, and operations without humans to realize a decarbonized society.

The benefits of factory automation, labor saving, and unmanned production include reduced labor costs and human error.

However, the hurdles to moving forward are high, and it is necessary to organize issues.

Quality Assurance of Unmanned Time

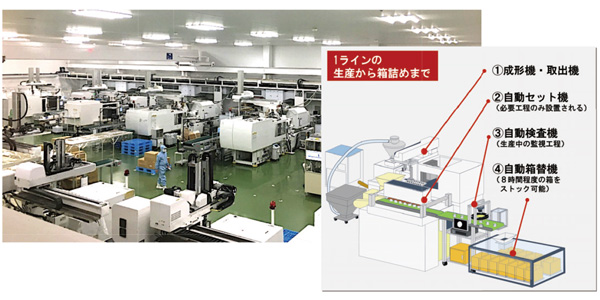

Aska Company's unmanned operation is set for 8 hours from 0:00 at night to 8:00 the next morning.

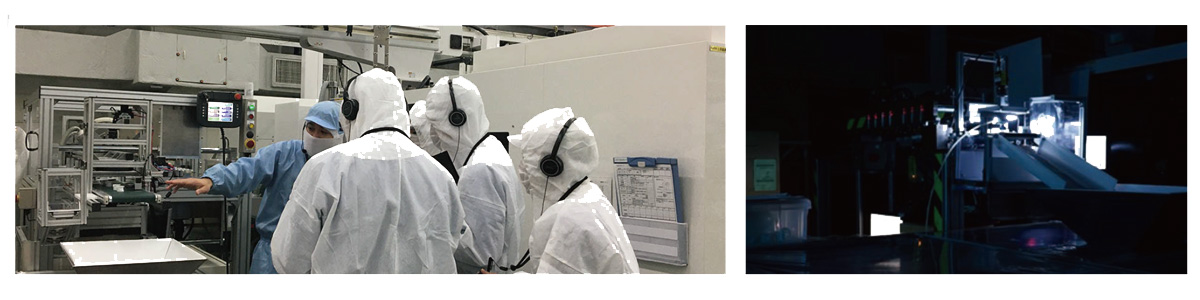

For quality assurance during the night when no one is present, IoT data such as camera inspections and machine condition monitoring are used.

We share information with the entire site during the morning meeting the next day.

Although unmanned operations may give the image of people being eliminated, since people (workers) analyze data obtained from machines,

it creates cooperative activities that take advantage of the respective strengths of machines and people.

Rather than completely eliminating people, we believe that factories of the future will need people to do what only people can do.

Machines that Support Manpower Saving and Unmanned Nighttime Operation in Factories

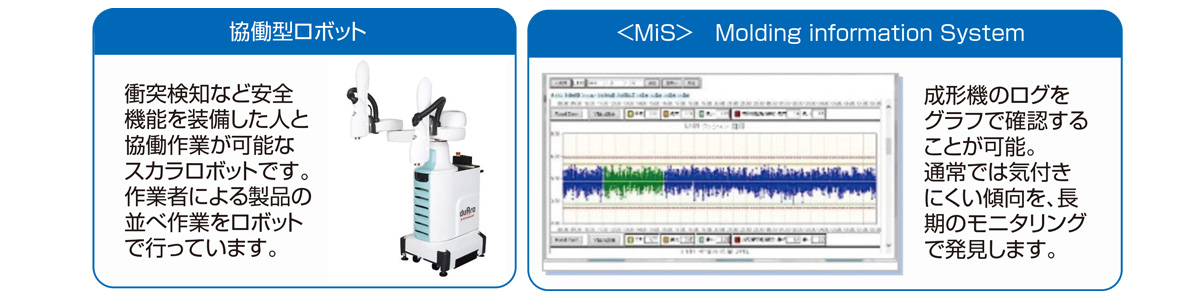

We have also achieved manpower saving and nighttime unmanned operation by utilizing IoT data through other tools

such as auto-stockers, short-shot detectors, and camera inspection systems that we developed and manufactured in-house.

We will continue to upgrade our workplaces by actively engaging in digital tools.

■Aska Company Seminars

For those who don't know where to start in advancing factory automation and unmanned nighttime factory operations, the Aska Company offers seminars on unmanned nighttime factory operations.

Based on our own case, we talk about the introduction of automation technology, the start-up of unmanned nighttime factory projects,

the creation of mechanisms, and quality assurance from both the "front-line" and "management" perspectives.

Nighttime Unmanned Seminar Overview and Schedule

The following is an example of a seminar held at our main factory (Kato, Hyogo Prefecture), but we also hold a seminar at Knowledge Park (Kami County, Miyagi Prefecture).

10:00 Explanation of Unmanned Factories at Night

- Introduction of Company

- Definition of Unmanned and Description of Aska's Production Line

- Problems of Nighttime Manned Production

- Steps Toward Unmanned Factories

- Know-how when Building Factories Suitable for Unmanned Operations

- Unmanned Project Details

- Effects of Unmanned Factory

- Quality Assurance of Nighttime Products Using IoT

11:20 Tour of Unmanned Factory at Night (S Site)

12:10 Discussion over Lunch

12:50 Observe Examples of IoT Application at a Manufacturing Site (N Site)

13:50 Custom Studies

Please select one of the following.

- Practical Resignation in the Early Stages of Camera Inspection Introduction

- Examples of Sensing Data Applications

- Explanation of the Mechanism for Activation of Project Activities

- Introduction of Project Activities/QC Circle Activities

14:20 Break, Q&A, Questionnaire

15:00 End

This 5-hour seminar is a fusion of IoT and AI with project activities and QC circle activities.

We hope you will take advantage of this seminar as a hint to reduce manpower and introduce unmanned factories!