MK is also making extensive use of digital technology.

Recently, words such as "IoT," "ICT," and "digitalization" have been used in various places.

We have begun to offer seminars using IoT and AI and quality assurance using camera inspection data.

It has become commonplace within the company to make it possible to view camera inspection results and molding machine status from afar in the form of data and graphs, and this has become quite widespread among workers.

Aska Company has been continuing QC circle activities named "MK activities." In these MK activities, people in charge of manufacturing processes frequently use IoT to give shape to their ideas.

We want to share an example of IoT utilization at MK.

We want to be able to work with warehouses away from production.

The activity period of MK is six months, and during that six-month period, we carry out improvement activities under the theme of problems in the workplace.

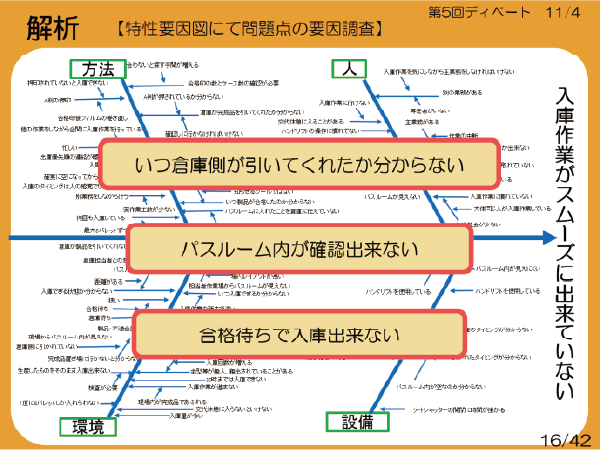

The goal of improvement was to make the warehousing process easier and faster. We set the goal based on the problem of "the warehousing process is not running smoothly.

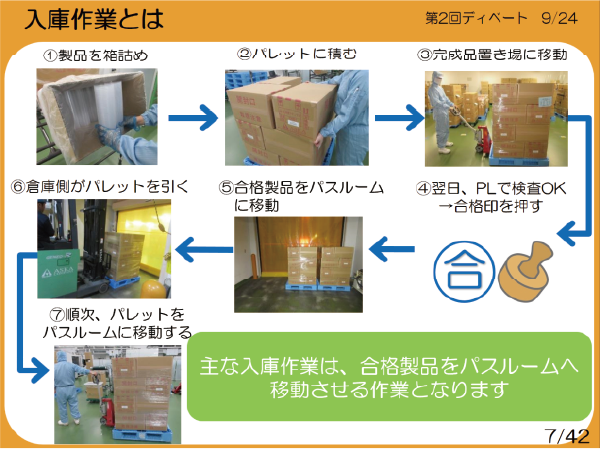

Incidentally, warehousing operation means "putting the products produced by the manufacturing side into the warehouse.

Explanations of these operations and processes are also part of the activity presentation. The ability to communicate in a simple, easy-to-understand manner without making mistakes is an important part of our work. We foster such ability through MK activities.

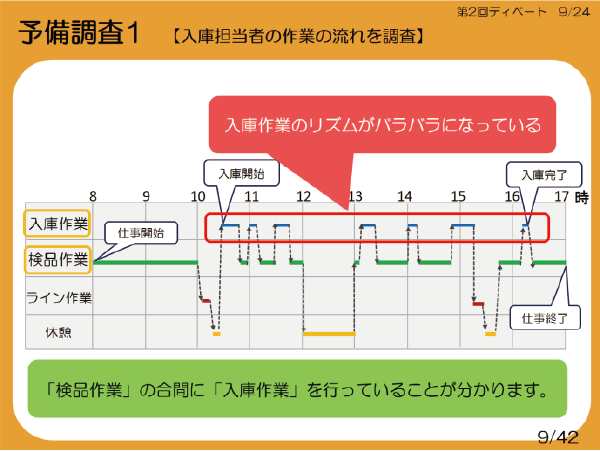

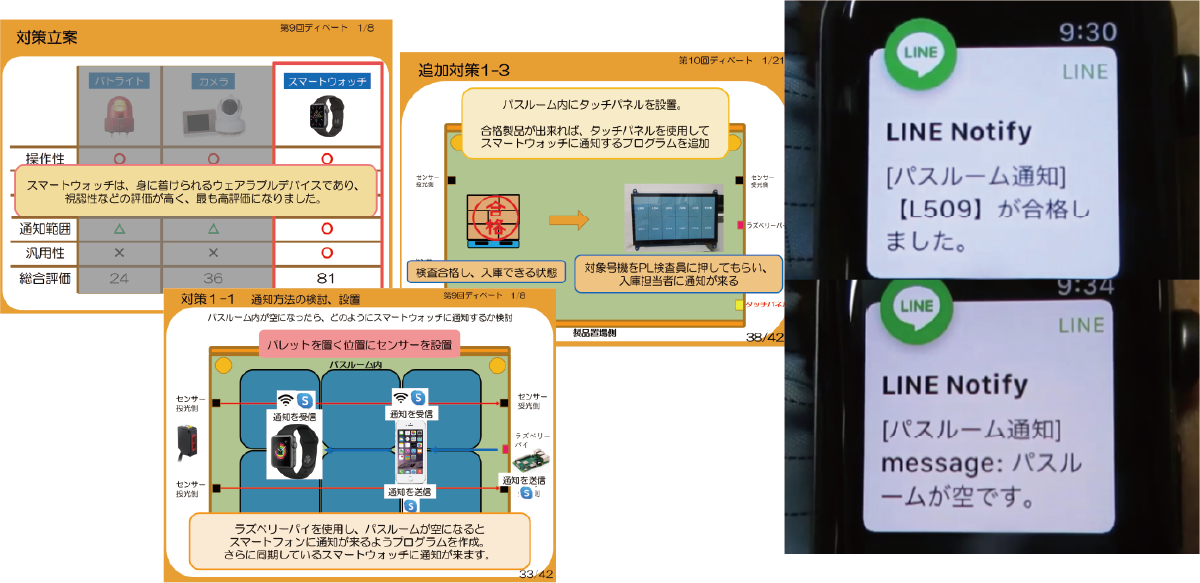

The problem one group had was the condition of the "pass room." "Pass room" is where products are handed over to warehouse workers. Once warehousing work was done, we had to check the condition by directly going there. It was hard to know when to put products there and required workers to frequently go check to see if products were there. That was a time-consuming process.

In MK activities, we should gather data theoretically by using QC methods. Since we are accustomed to using QC methods, we can naturally think in a QC way in our daily work.

Proposed and Improvement Measures

In addition to camera inspection data (MyCiS) and molding machine data (MiS and CFM), Aska Company collects data on product start-ups using a mold change application (KTG).

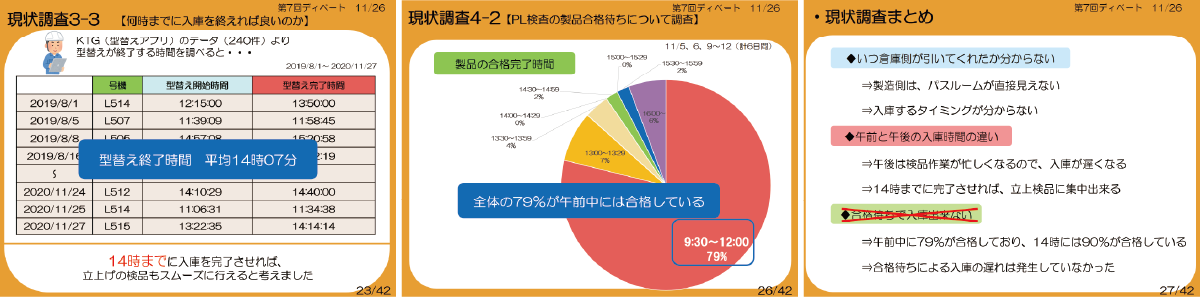

We gathered information using data on product start-up operations from the mold change application. Then we collected production information data on product inspections from the database. By utilizing these data, we could determine what time it was necessary to receive products into the warehouse. As a result, we found that most of the product inspections had been completed by mid-morning and that the warehousing operations were ready to begin.

Aska Company has been experimenting with various new approaches. We are not afraid to use new devices.

For this measure, we chose a wearable device called a smartwatch from the place where "we want to see the data freely." The measure was to transmit the inspection results via a touch panel to manipulate the information more freely.

We believe that we chose such measures because of the soil of IoT utilization, where various data are collected and utilized.

Would you like to experience the use of IoT and AI?

Aska Company has been operating various systems to utilize data in various places and forms.

We provide our know-how through IoT/AI Utilization Seminars and Nighttime Unmanned Operation Seminars. We also incorporate newly developed tools and systems into our seminars as they become available.

We are constantly evolving our factories and tools, so if you are interested in learning more, please join us for a seminar.