Thank you very much for always reading our market news.

At Asuka Company, we are building a new spout pouch development system centered on the “development mold” we introduced previously in order to further increase the speed of our proposals to customers.

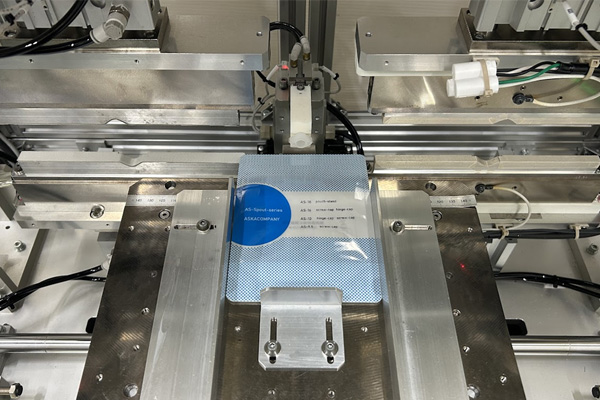

This time, in order to realize the shapes and functional tests desired by our customers more quickly, we have introduced a spout welding testing machine, enabling us to make proposals using spout pouches that can be tested with actual contents, in addition to the shapes of spouts and caps.

The newly introduced spout welding test machine operates manually.

While the number of weldable units is limited due to its manual operation, it offers flexibility that is not easily affected by the shape or form of the bag.

By providing samples of our spouts welded using this spout welding test machine, we can now clearly propose how they can be used, whereas previously, when proposing spouts or caps alone, it was difficult to visualize how they would actually be used.

Additionally, this machine supports the development of new spout shapes by enabling internal verification of the relationship between spout shape and welding defects, as well as evaluating the functionality of spout pouches.

This machine is a prototype machine, so it is not possible to provide actual products for sale to customers using this welding test machine. It is solely intended for “prototype purposes” leading up to the actual product.

Proposals that demonstrate ease of use

With the introduction of soldering tests, we are now able to propose spout pouches to our customers.

One of the features of our products is the “functional hinge cap.”

We can now prepare spout pouches with contents and capacities similar to those used by our customers and demonstrate the “discharge adjustment valve” function, which allows for adjustment of the discharge amount, in front of our customers.

Customers can now check the ease of opening the cap, the ease of holding the pouch, the position of the spout, and other details using the actual product, allowing us to make more flexible proposals that better understand what customers are seeking.

Various spout pouches available

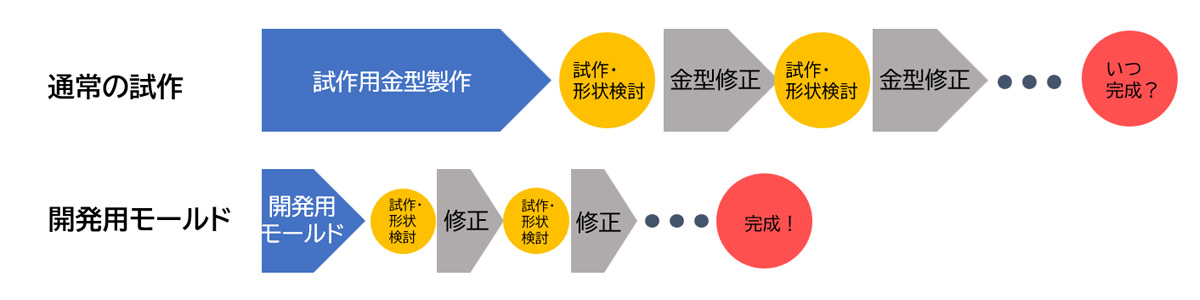

“Development molds” enable short-term spout development.

Our company has the capability to verify model shapes using 3D printers, but in order to verify functionality, such as whether it can be welded as a spout pouch, it is necessary to produce a mold and form the actual resin into a molded product.

However, since mold production requires several months, we have established a system that can provide molded products with functionality in a short period of time for development purposes.

Using this system, it is possible to produce molded products that can be welded in as little as two weeks.

-

-

Introduction of Mold Fabrication for Development [ASKA MARKET NEWS Jul. 2025, No. 365].

Thank you for reading Market News. Aska Company has been developing products using molds called development molds in order to speed up the development process. In this issue, we would like to introduce our Rapid Mold production process. Please note that the development molds are used for our own AS series products and are not applicable to the process of commissioned development of customer's products. Translated with DeepL.com (free version) What are development molds? Development molds are simple molds that enable product development at low cost and in a short period of time. It is possible to use actual molding ...

A system that can quickly respond to even prototype spout pouches

Our company is capable of designing and manufacturing molds in-house, enabling us to perform metalworking such as the production of development molds.

In order to perform spout pouch welding, a welding plate that matches the welding area is required.

When a new spout shape is created, it is necessary to create a matching welding plate, but since we are capable of manufacturing welding plates in-house, we can respond relatively quickly.

Since there are processing specialists within the design team, we can quickly adapt to any changes in the spout shape during development and promptly provide customers with samples of welded spout pouches.

Using the spout pouch welding and efficient spout development methods we have introduced, we will bring your desired spout pouch design to life. Please feel free to contact us for more information!