"Quality" speaks volumes about the results.

Our persistence in achieving zero complaints drives us to pursue the path of dedicated technological study.

We actively adopt IoT and AI technologies to improve quality by accumulating and analyzing information from image processing inspection cameras, molding machines, and other sensing devices.

We are polishing our data analysis technology and aiming to realize a factory automation system.

"IoT -Internet of Things- Plants supported by people produce only good products."

Productivity

Automation and Unmanned Production Plants

The keywords "unmanned" and "automation" is the keywords that the production system aims for following the characteristics of each factory.

Factories that have already achieved nighttime unmanned operations aim for further unmanned operations.

In such factories, equipment monitors product quality in pitch-dark conditions.

See "Nighttime Unmanned Factory Seminar">

Biological Clean Room (Dust and Microorganism Control)

In addition to dust control, the plant also controls airborne bacteria and contamination and takes thorough measures to prevent foreign matter.

Our production system using biological clean rooms where we control dust and microbial contamination, which we have cultivated since 1984, has been refined to achieve a high management level.

Diverse Production Machinery

We have a variety of machines to meet the diverse needs of our customers.

《Examples》

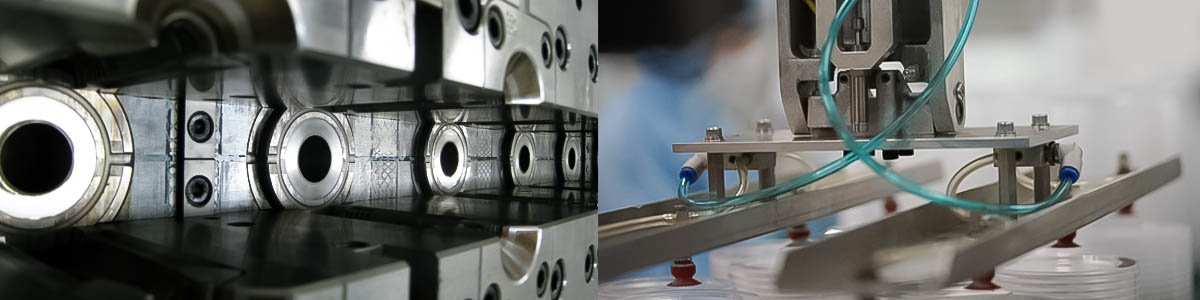

Injection Molding Machine Sizes from 75 to 350 tons, high cycle machines to precision molding machines

In-mold molding system In-mold molding system for high-cycle molding

Extrusion molding machine Small lot masterbatch production applications

Forming-linked packaging machine Four side seal continuous packaging machines and dedicated applicator can be provided

Reverse pillow packaging machine Packaging machine for small lots of spoons, etc.

Dry offset printing press High-speed printing machine for cup sides

Sterilization Services

Sterilization, such as electron beam sterilization, is also available according to the level of sterilization requested.

Product Quality

Commitment to Source Control

Instead of working with the idea of finding and eliminating defective products, we have continued to follow the philosophy of

"creating a state that we only make good products by controlling the source of the problem."

We have been conducting a wide variety of detailed source control,

from the temperature and humidity of the production plant to the maintenance and storage methods of molds to the quality of the mold cooling water.

The Challenge of 100% Inspection

In any product, there are fatal defects that should not exist.

To prevent such defects, we have installed visual inspection cameras. These cameras are all for traceability and a quality assurance system.

Use of Image Processing Inspection

We independently have built inspection lines using visual inspection cameras by in-house technology.

Based on the use of available image processing inspection cameras, we have established our image processing method using the open-source OpenCV image recognition library.

We are actively introducing image processing inspection cameras to our production lines.

We conduct quality control using statistical data from inspection results, not only Omni-directional inspections.

In addition, as an incentive for those who have yet to introduce image processing inspections, we also offer a seminar to experience visual inspection cameras based on the introduction technologies of cameras.

Image Examination Statistics Display System MyCiS (My Camera Infomation System)

Aska Company's image processing camera line discharges defective products. At the same time, it accumulates the data, and we utilize that data.

MyCiS, which aggregates camera inspection results and visualizes the quality of the production line, makes it easy for anyone to identify trends in defects.

The system based on behavioral science naturally creates a "state where people think and act," and the quality level rises according to the strength of people.