In this issue of Market News, we would like to introduce the automatic control of air conditioners in the production area of our headquarters S/N Factory as an example of the use of IoT.

In our production area, several air conditioners are set to cooling all year round due to heat dissipation from the molding machines.

However, the settings are constant regardless of high or low outside temperatures, and the number of air conditioners had not been reviewed.

This time, we have taken steps to automatically control the air conditioners so that only the necessary amount of electricity is used while maintaining the room temperature in the production area.

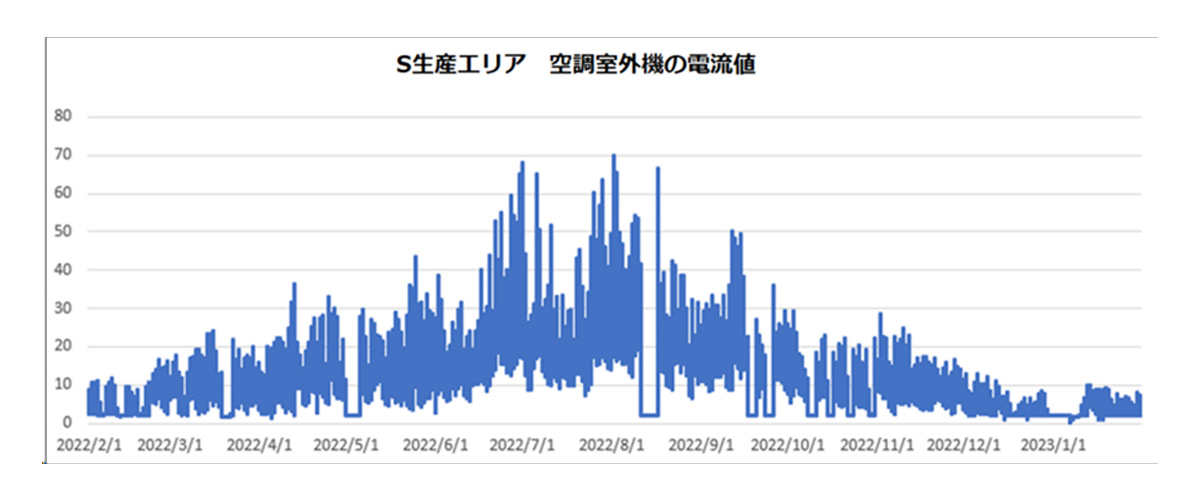

Grasp the operating status of HVAC equipment

First, to determine the operation status of the outdoor units, we installed a current value measurement kit in the switchboard and obtained current values for one year.

As a result, we found that the current values were low in winter when the outside temperature was low, and that only two of the six units were in operation. In addition, there were also events that repeated ON/OFF in a short period of time depending on the time of day.

We found that the indoor unit automatically switches from the cooling setting to the air blowing setting in winter when the outside temperature is low, and that it operates unnecessarily.

Air conditioner operation that does not rely on human intervention

To eliminate unnecessary operation, temperature and current data were used to automatically turn the air conditioner on and off while maintaining room temperature in the production area.

Switchbot was used to turn the air conditioner on and off. Switchbot is linked to the equipment to enable remote control. Switchbot was installed in all six air conditioners.

SwitchBot (SWITCHBOT Products)

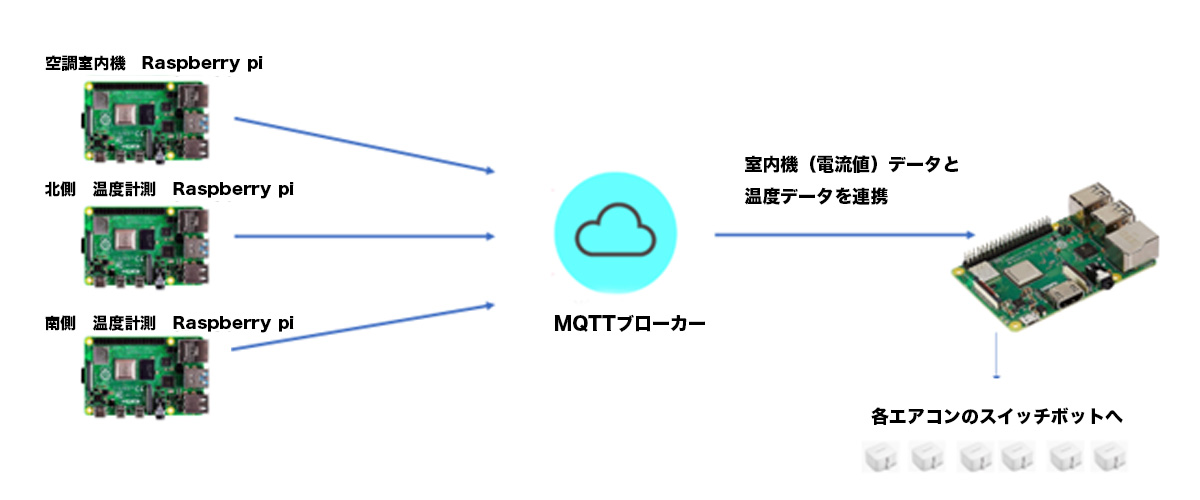

Build automated systems by linking data

Data obtained from a Raspberry Pi (a small single-board computer) that measures temperatures in the production area and from a Raspberry Pi that measures the current values of indoor units were linked to specify the optimal time and room temperature for turning each unit on and off.

By linking the data and building an automated system, it became possible to operate the air conditioners without relying on human operators.

MQTT(標準プロトコル)を使用した機器の連動のイメージ

What is the effect?

As an effect, in the five months from January to May 2024, when the experiment was conducted, 76.1 MWh less electricity was consumed than in the same month of 2022, a reduction of approximately 71%.

The annual estimate is expected to reduce electricity by 170.7 MWh.

At Aska Company, mechanisms for utilizing sensor data are in operation in various places and forms.

We offer our know-how in the form of seminars, so please contact us if you are interested in these.

We will continue to contribute to our customers and a decarbonized society by improving production efficiency through further IoT and the use of data.

I