In this issue of Market News, we would like to introduce some examples of internal use of MyCiS (Statistical Display System for Image Inspection).

First, let us explain MyCiS.

MyCiS is software that "uses data from camera inspection results to visualize and share production status to improve quality and productivity.

Products molded on a molding machine are taken out on a conveyor, and camera inspections are performed on the conveyor to make inspection decisions on appearance, dimensions, and other factors.

Even a single line is inspected 24 hours a day by multiple cameras from all directions, and the camera inspection system provides data.

The role of MyCiS is to organize and analyze this vast amount of data and make it easy to see the status of the process.

【Example of MyCiS Application to Spout Set Products】

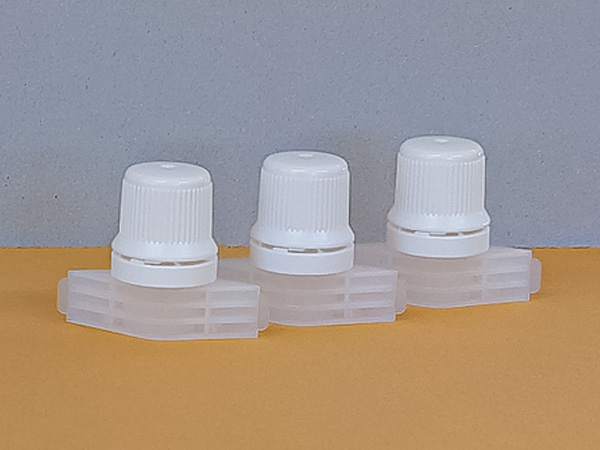

We mold spouts and screw caps and set the caps on the spouts as a secondary process.

An automated assembly machine performs the setting process. Then the camera inspection equipment and various sensors make an inspection judgment.

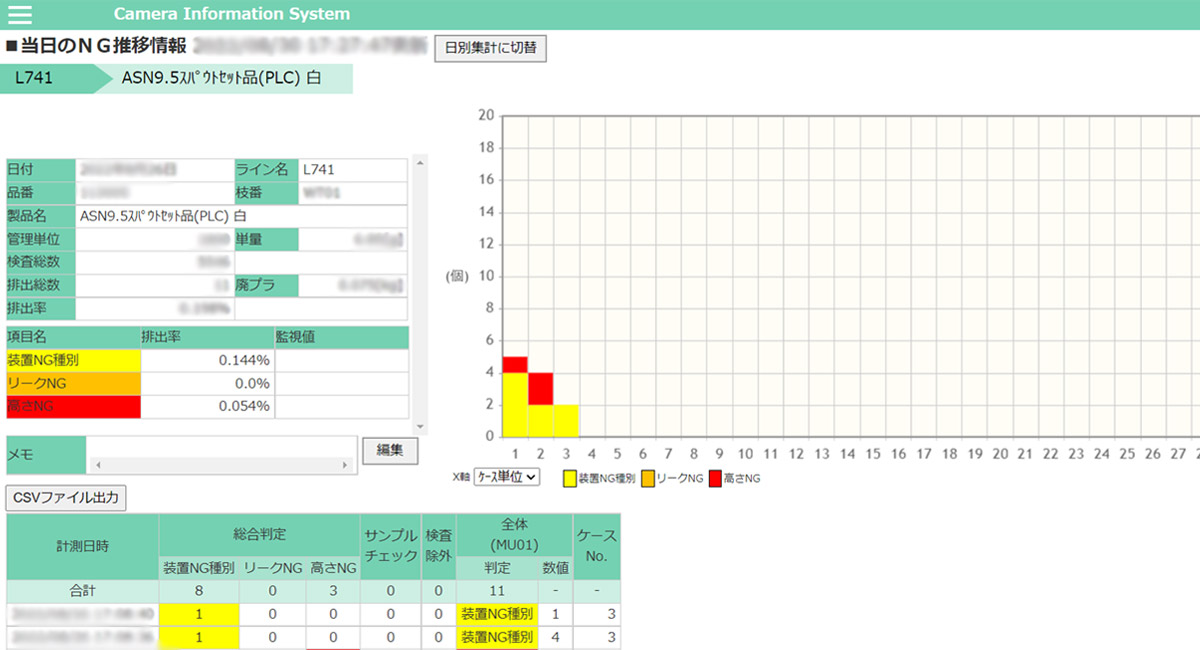

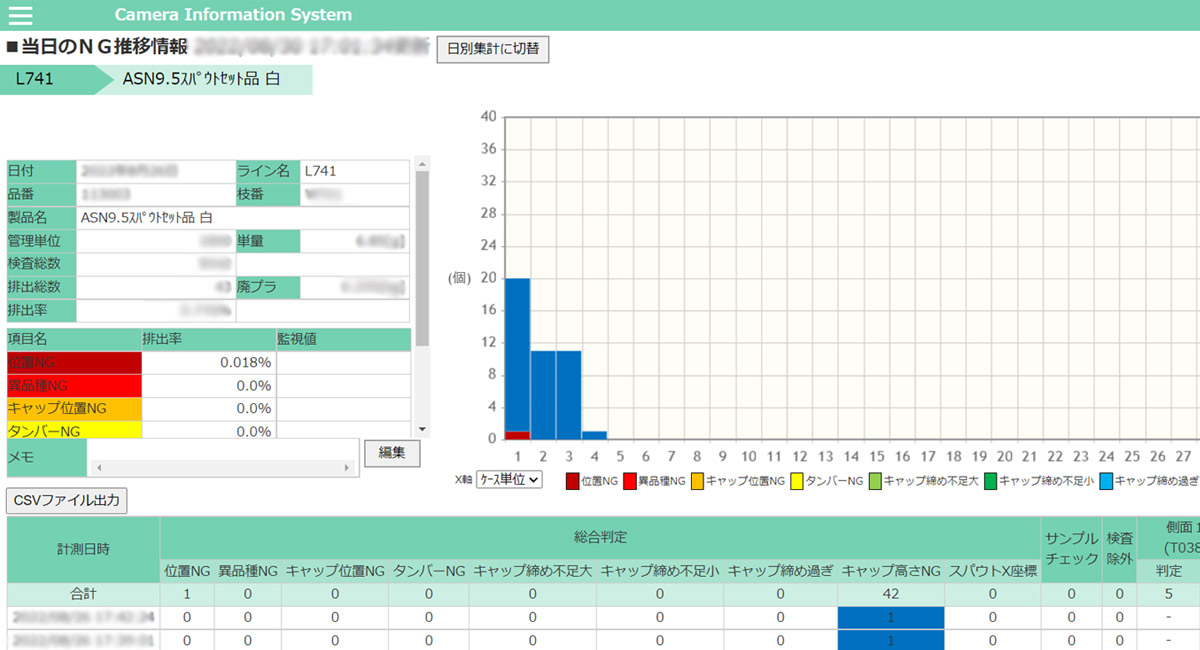

MyCiS monitors the inspection data.

Set machine monitoring items

- Image Processing (Camera Inspection) 7 Items

- Pressure Sensor (Leak Test) 1 Item

- Contact Sensor (Height Detection) 1 Item

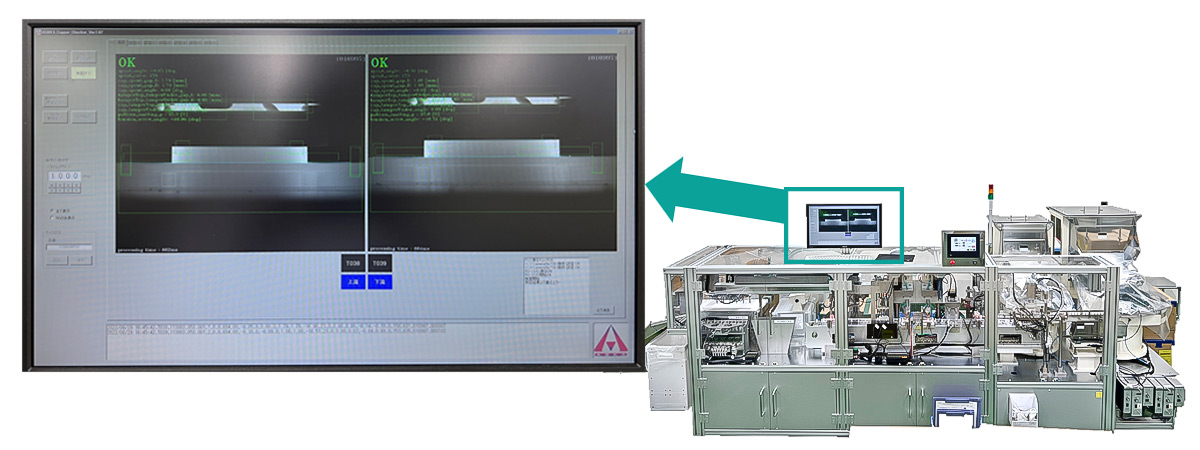

Left: Camera Inspection Screen of Set Machine / Right: Automatic Assembly Machine (Setting Machine)

Set machine monitoring items

As shown below, MyCiS manages items separately

on the camera side and on the PLC side (various sensors).

- Camera side: 7 items such as checking for tamper breakage, product position, etc.

- PLC side: Leak inspection of liquid leakage and various sensors

Substitute measurement of the total height of the set as confirmation of tightening torque