Labor Saving and IoT in Plastic Injection Molding Plants

Plastic injection molding is based on a 24-hour production system.

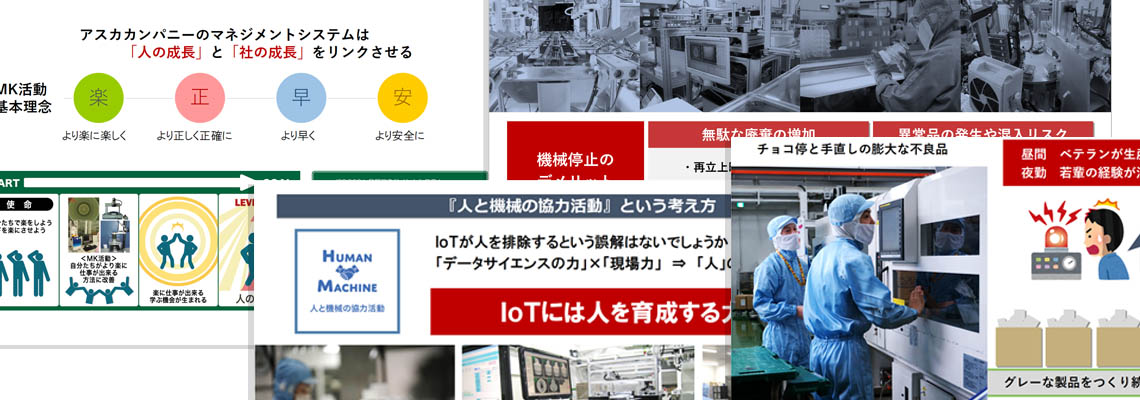

Aska Company operates a completely unmanned factory at night with our own technology based on the concept of "source control," one of the management principles cultivated through QC circle activities started in 1978.

Quality control methods are naturally connected to the realm of IoT and AI, and "collaborative activities between humans and machines" are conducted at the factory, leading to a smart factory and operation.

In the lecture, we will share with you the history of the challenge of unmanned factories, which started in the 1990s with the operation of a single unmanned machine, and the introduction of camera inspection, as well as the path to unmanned nighttime operation.

You will be able to see the facts as we also operate unmanned during the lunch break from 12:00 pm to 1:00 pm.

In addition, we will conduct a factory tour on site to show the operation of IoT.

We hope you will use this seminar as a hint for introducing unmanned factories.

We welcome visitors from different industries other than plastics manufacturing, so please feel free to contact us for more information.

Translated with DeepL.com (free version)

Acquire Know-How while Touring the Factory.

We will convey the contents in the form of "hands-on" experience of how to proceed and practice nighttime unmanned operation and human resource development, which we have gained through our nighttime unmanned operation from both "management's perspective" and "technical perspective".

We will tour two factories at the Aska Company headquarters and introduce the advantages of both nighttime unmanned operations and quality assurance through the use of IoT and how to combine the two.

This seminar is designed to provide a variety of perspectives to managers, executives, and front-line workers.

We look forward to seeing you at this seminar.

Seminar Overview

1.Open to 1 company only

Unlike regular seminars, we hold this seminar only for one company.

Since there is no one from another company, we can customize the content as much as possible.

Also, you can freely ask questions as much as time permits.

2.You can tour a nighttime unmmand, IoT-Utilizing factory.

The tour will visit a manufacturing plant where nighttime unmanned operation is in place and various explanations will be given in front of products.

As part of the hands-on tour, participants will also take part in a daytime meeting, and experience actual operational situations at a manufacturing site where IoT is utilized.

You can experience how quality control and IoT cross each other and how important they are.

We use high-functioning headsets so that everyone can share questions and answers in the factory.

3.You can see 'real' how people thought and created it.

We will explain the measures taken in QC circle activities, which is one of our company's strengths, and the equipment, etc. that we actually created out of our worries, using the materials and equipment as they are.

We will explain the ideas at the time of factory construction, the equipment installed, the reasons for creating the system and its operation, all using screen.

We have devised a system that can be understandable even by those with no knowledge of the plastics manufacturing industry.

Seminar Contents

We focus on "hands-on experience" as much as possible so that you can understand various applications in a short period of time.

Our nighttime unmanned factories were not built by people with technological superiority, but were created and operated by people who think.

This seminar will provide information on how we are implementing nighttime unmanned operations from both management and technical perspectives.

1. Description of Unmanned Factory

Aska Company's approach to training people, the definition of nighttime unmanned operation, and the concept for operation.

We will explain how production lines and plastic molding in production plants look like, along with the disadvantages of machine stoppages.

2.Nighttime Unmanned Factory Tour

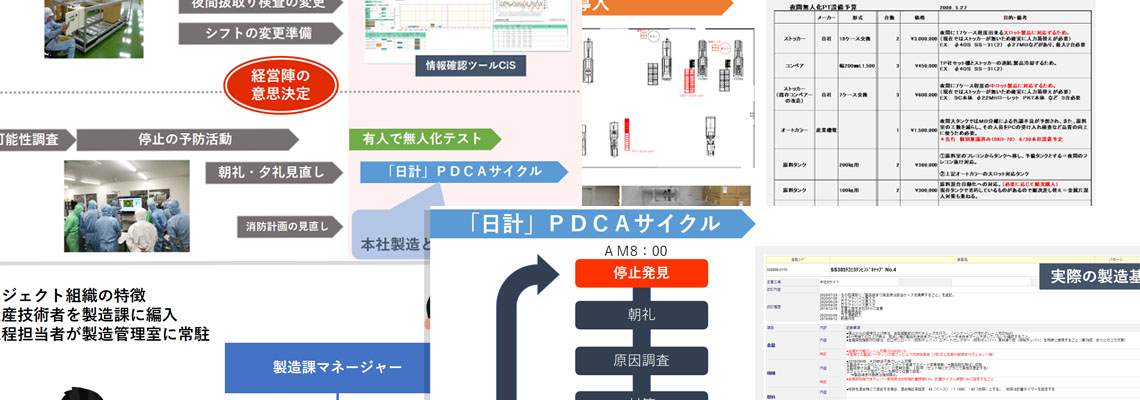

The presentation will include construction concepts for unmanned nighttime operation, operation of actual equipment and quality assurance through data.

3. Lunch (Q&A over meal)

You can exchange various opinions over a meal.

4. Experience IoT Application at the IoT-Utilizing Factory "N Factory"

You will experience the factory daytime meeting where IoT is being utilized.

The tour will explain what kind of information is being checked and used, and what kind of information is necessary, while observing the state of use.

5.Installation of Automated Inspection Lines and Data Operations

Based on the project we undertook to implement unmanned operations, we explain the internal organization and structure of the company with documents from that time.

We also introduce the concept of quality assurance during unmanned nighttime conditions by linking unmanned nighttime operations with the IoT.

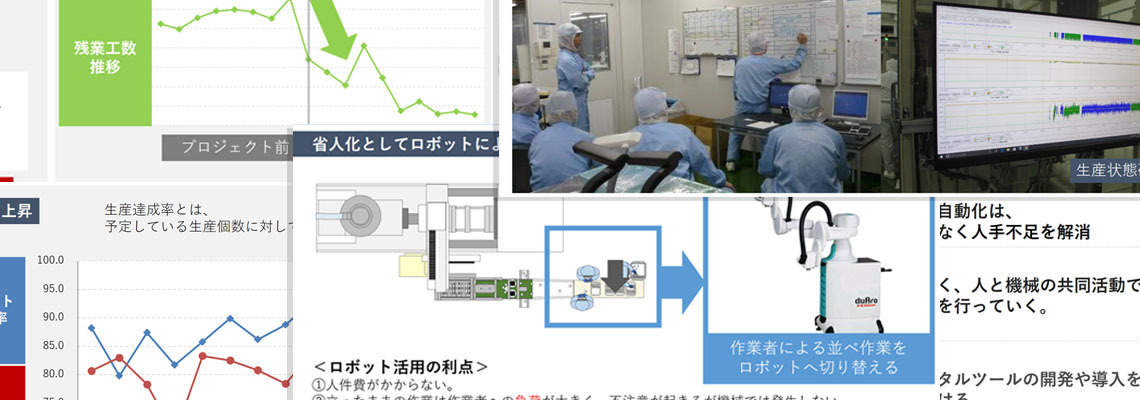

6.Effects of Unmanned Nighttime Operations and Human Resource Development

The presentation will include the development of human resources who think spontaneously and the quality effects of nighttime unmanned operations, the concept and way of proceeding with the use of IoT and AI in Aska Company, and future prospects.

Testimonials from Participating Customers

Fee, Number of Participants, and Location

[Number of Participants]

Courses are available for one company only.

From 1 to 4 people.

[Fee]

150,000 yen (excluding tax) ※The cost is the same for one course, whether the seminar is for one person or three people.

Lunch will be provided.

[Location]

Head office and factory of Aska Company (Takino-Cho, Kato City, Hyogo)

We will take you on a tour of the production plant at our factory.

※We will also provide transportation support (Shinkansen to Shin-Kobe and Himeji stations, Itami Airport, etc.).

It will take about 1 hour to get to our company from the station or airport.

There are accommodations such as Route-Inn near our company.

Aska Company Knowledge Park (Kami County, Miyagi)

We will tour the production plant in Knowledge Park

※We will also provide transportation support.

Pick-up support is available at Furukawa Station (Tohoku Shinkansen and Rikuu Higashi Line).

It will take about 30 minutes to our company.

Accommodations are available nearby.