This product is no longer available.

"Visualization & Sharing" of camera inspection improves quality and productivity!

Is the camera inspection used only for OK or NG decisions?

Image inspection cameras can eject defective products and data from inspection results.

MyCiS is software that aims to improve quality and productivity by visualizing and sharing production status using data from camera inspection results.

【Contents】

3. Effects of operating MyCiS【Visualization of Production】

1)Easy to check camera inspection results.

2)Able to share inspection results.

3)Information can be stored for a long time.

4. Effects of operating MyCiS【Improving quality and productivity】

1)Able to manage production line trends.

2)Preventive maintenance against defects is possible.

3)Can be applied to ISO 9001.

1. What is MyCiS

MyCiS is "software that provides inspection results from image inspection cameras in a form that is easy for anyone to understand."

And when used in conjunction with on-site knowledge, it can be expected to improve quality control and productivity.

If many cameras are installed on one product, can you quickly figure out which camera is inspecting which part of the product?

With MyCiS, there is no need to understand such difficulties.

Camera inspection results are aggregated for each product, and any worker can check the status by simply using the product name.

Camera inspection results are also the result of the quality.

By aggregating these results, it is possible to grasp the goodness or badness of the entire production site.

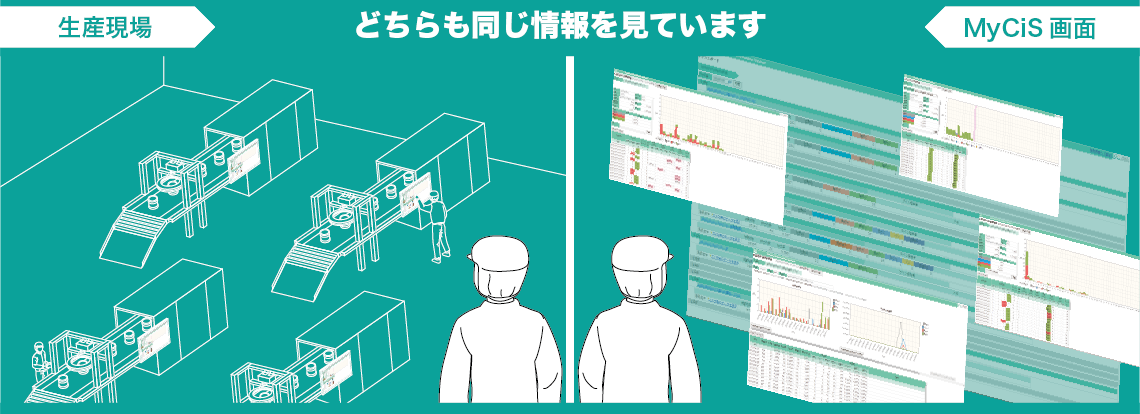

With MyCiS, you can grasp the production status on a single web screen known by the operators on the production floor.

Not only can the production status be shared over the network regardless of location, but it is also easy to track changes in production status over a long time.

2. Need for MyCiS

The development of MyCiS began with a request from a manufacturing site: "We want to know what the results of camera inspections look like."

Aska Company has introduced cameras as a means to install & manage camera inspections ourselves.

Camera inspections not only inspect and eject defective products but also output inspection results.

The inspection results were all numerical and complicated for people to see.

People will naturally start to think when they are surrounded by an environment where information can be utilized in various areas,

such as on the manufacturing floor, in the inspection section, and in process design and when.

We want to know the reason why defective products are increasing.

We want to avoid the same dangerous conditions that occurred before.

Using the information from MyCiS as a clue,

we began to aim to improve quality and establish a system that does not create defects by making improvements and analyzing trends in defect occurrence.

By introducing one software, we can create something that did not exist before.

The ability of camera inspections is not limited to eject defects but is also used to control and improve quality.

That, in turn, will lead to "improving productivity and a risk management system for the company."

We are confident that MyCiS will produce benefits.

3. Effects of operating MyCiS【Visualization of Production】

1)Easy to check camera inspection results.

MyCiS visualizes camera inspection data on multiple Web screens.

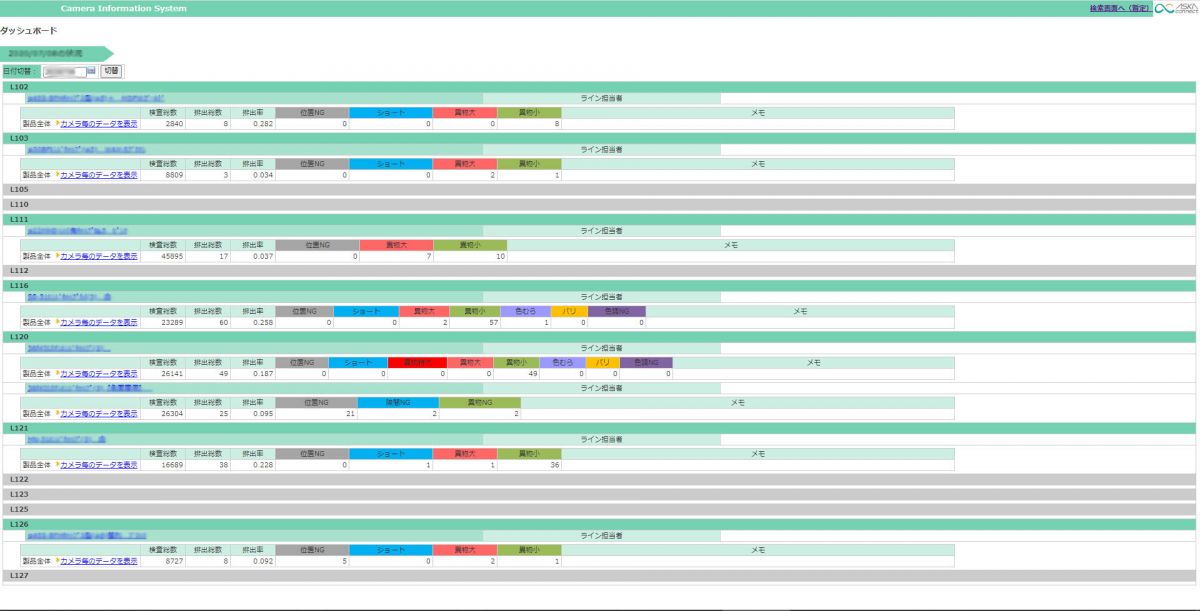

【Dashboard】to grasp the overall data

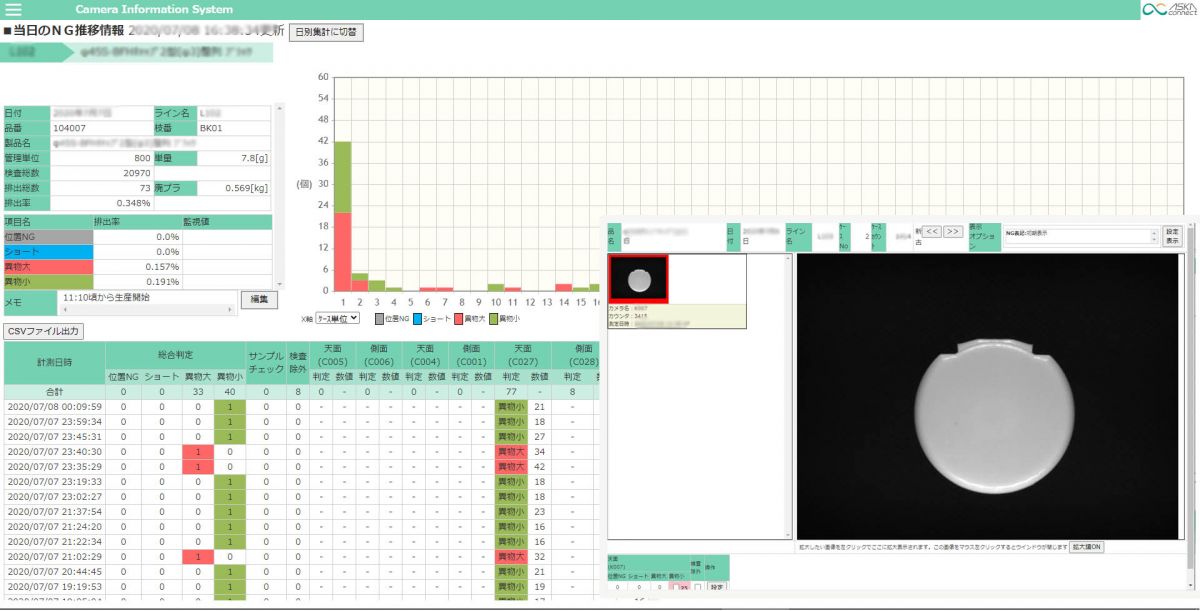

【Same-day data screen】for checking one day's worth of same-day information

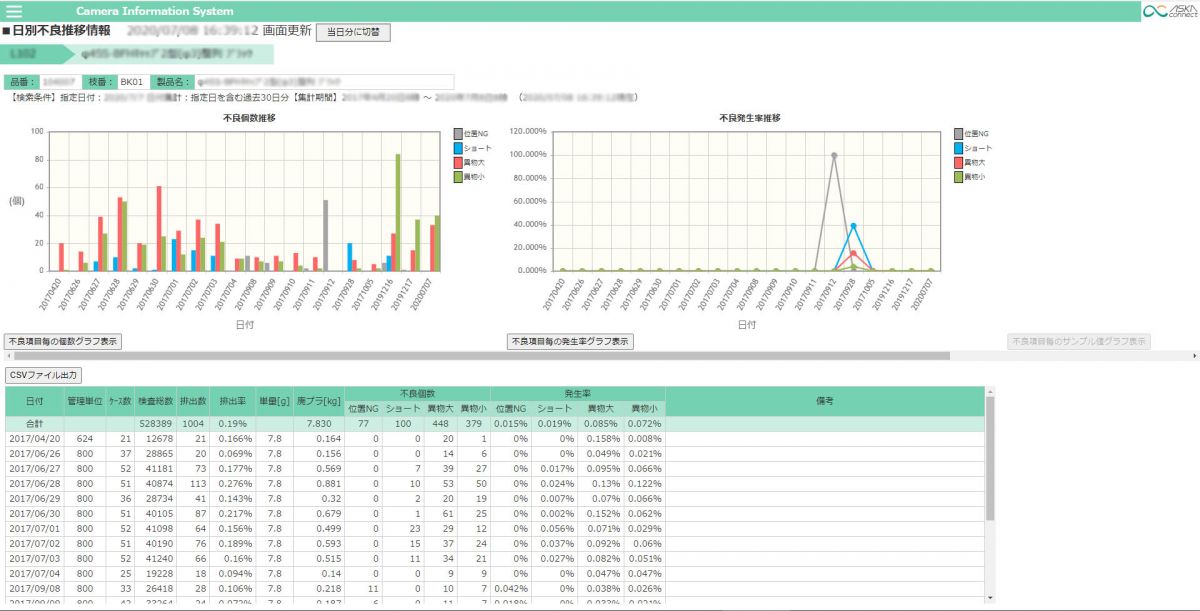

【Daily data screen】to check the occurrence of defects over a long period.

From these screens, problems can be quickly identified, such as "when and what kind of defects have occurred," enabling early response and improvement.

Dashboard

・Lists all registered line statuses

➡ View and manage the entire production on one screen.

・ Periodic automatic data update

➡ Real-time status of the line.

・ Notification when an arbitrarily set failure rate is exceeded

➡ Early detection and response to abnormalities.

Same-Day Data

・ Stacked bar graph display with different colors for each defect

➡ Anyone can intuitively grasp the status of defect occurrence.

➡ Numerical identification of the type and degree of defects.

➡ Supports efficient inspections by targeting the time of day when defects are most prevalent.

・One-click confirmation of defective images

➡ Identify and view images you want to check, such as critical defects.

Daily Data

・Displays the number and rate of each defect for up to one month

➡ Inference of abnormalities due to changes inside or outside the process.

➡Monitoring for change points.

➡ As a guide for creating standards and criteria for maintenance and control points.

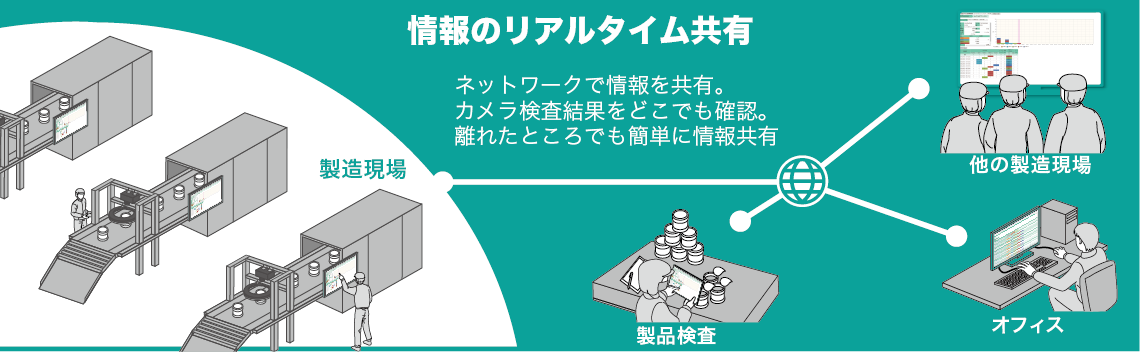

2) Able to share test results.

MyCiS utilizes IoT technology to visualize information.

We can share information via a network even at a distance from the manufacturing site.

・Sharing defects with other manufacturing sites.

・Condugcting inspections based on an understanding of the conditions at the manufacturing site.

・Production control department and managers can understand the state and change the process.

Various responses are possible.

3)We can store the information for a long time.

MyCiS provides information in graphs and makes it easy for the human eye to check the information.

We can view this aggregated data at any time in the past.

In addition, the server stores all data acquired from the camera inspection machine.

The server saves the text data of the inspection results as CSV files and all the images rejected during the inspection.

That allows us to use raw data when complaints or other problems occur.

4. Effects of operating MyCiS【Improvement of quality and productivity】

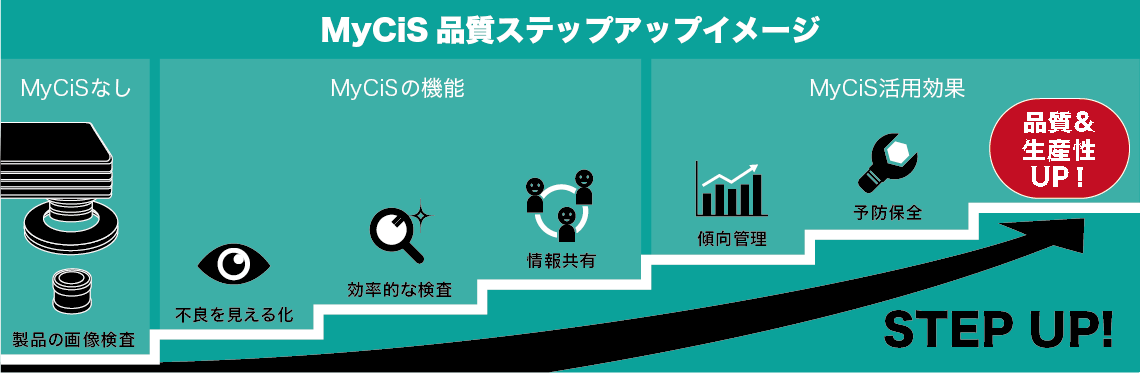

Without MyCiS, you only inspect products by camera inspection.

With MyCiS, you can see and check defects easily and efficiently, and you can share information.

That is just the beginning.

Do not be satisfied with just being able to see the state of production; you can aim for better quality by utilizing the visible state.

It can also be a way to prevent problems that will occur in the future, such as analyzing and managing trends in

defects, and preventing and responding in advance to defect risks.

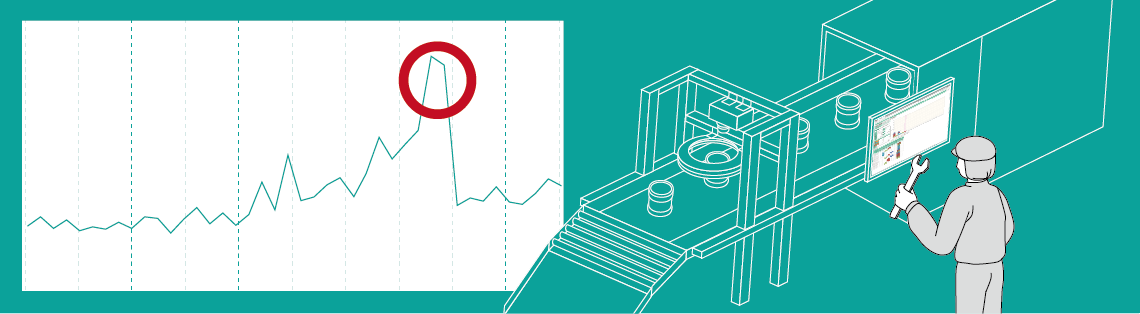

1)Able to manage production line trends.

By looking at not only the data of the day but also the past 30 days of defects for each product, it is possible to grasp the daily status of the production line.

For example, if the number of defects is slightly higher than that of the previous day, and same thing lasts for five days, it means the number of defects is considerably higher than five days ago.

Long-term management allows the daily accumulation of the daily changes to be subject to control.

2)Preventive maintenance against defects is possible.

The change point inside or outside the process may not be visible to workers or managers.

If you can't grasp the change point, it makes difficult to find what occurred and when.

Quality control with MyCiS allows you to keep a record of changes by graphing what kind of changes occur and when they occur by leaving notes at the time of work.

3)Can be applied to ISO 9001

The use of camera inspection data by MyCiS can be applied to "performance evaluation" and "improvement" under ISO 9001.

| ISO 9001 Items | Monitoring & Measurement | Analysis | Evaluation | Non-conformance and corrective actions |

| Utilization of MyCiS | Collect data from cameras | Visualize and understand information with MyCiS | Trend management and preventive maintenance | Feedback of information |

5. How to install MyCiS

The "Image Processing Inspection Statistical Display System (commonly known as MyCiS)" is software that utilizes the IoT.

In order to use the system, you need to install the necessary equipment and LAN network.

※Professional contractors should install a LAN network.

The simple flow is as follows.

①Acquire data from image processing camera equipment using a PC for data collection.

※Use the dedicated MyCiS software.

②Acquired data is sent to the dedicated MyCiS server, where it is stored and compiled.

③The data can be viewed from any terminal connected to the network by the web server function.

Two types of MyCiS are provided to suit your needs: 【1-PC Version】 and 【Server Version】.

| 【PC specifications for data collection】 | 【MyCiS Server Specifications】 | Applications and Remarks | |

| 1-PC Version | ・OS: Windows 10 64bit ・RAM: 16 GB or more ・Storage: Depends on the amount of data to be stored ・Ethernet: 1000Mbps or higher recommended ※CPU, etc., according to the capabilities of the Cognex camera |

Provides MyCiS as a virtual server inside a data collection PC See PC for data collection for specifications. |

For small-scale production, such as one production line |

| Server Version | Basically follows the capabilities of Cognex cameras Storage depends on the amount of camera data to be stored |

The capacity of the physical server varies depending on the amount of data used and the network, so proposals are made after consultation according to usage requirements. | For multiple lines |

Terminal Requirements for Data Verification

・Web browser supporting javascript (javascript is used for display and response)

・Tablet or monitor capable of FullHD display (scrolling is required for lower resolutions)

Network

・Ethernet for data collection PC side (camera data collection): 1000Base or higher LAN communication

※Communication cannot be guaranteed with 100Base.

・【MyCiS Server】Ethernet for information confirmation communication: LAN communication of 1000Base or higher

Target image inspection camera manufacturer

・Cognex image inspection camera equipment (prior confirmation of equipment used, data aggregation method, etc. is required)

※Other manufacturers' equipment, such as Keyence, are available upon consultation.